| Control | |

|---|---|

| Type | Sinumerik 828D |

| System software | SW 28x |

| CNC memory | 8 MB |

| Set change time | 1 ms |

| Look Ahead | 150 |

| Number of tools | 512 |

CNC milling machine

OPTImill F 210HSC

High precision, solid construction, effectiveness and economy

Price upon request

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 3511222

Productdetails

- Siemens Sinumerik control 828D with 15.6 inch touch display

- Difficult execution

- High productivity

- High reliability

- Profile rail with roller circulation for high rapid traverse speeds and high load capacities

- Machine lamp in the workroom

- Automatic lubrication

- High-torque servo drives in all three axes

- Strongly ribbed, torsion-free machine base

- Massive, exact milling table with four T-slots, large dimensions and precision ground

- Portable, electronic handwheel

- Chip conveyor in belt design ensures efficient chip removal

- RJ45 connector, USB port and power connector 230V

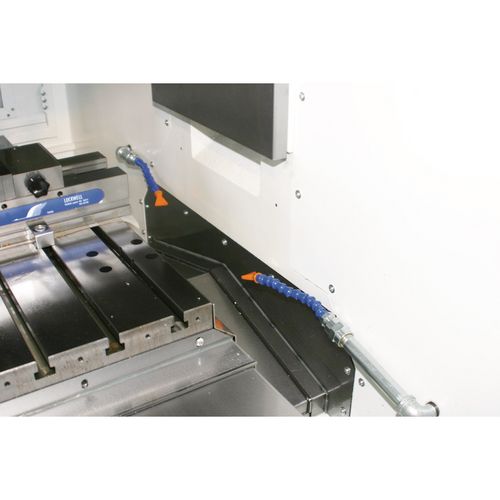

- Coolant system with 370 liters coolant tank and chip flushing system

- Closed control cabinet with integrated heat exchanger ensures optimum temperature and prevents the ingress of dirt particles

- Telescopic guideway cover on all three axes

SINUMERIK 828D - The powerhouse in the compact class of CNC controls

First choice for every machining technology

- Even at the highest processing speeds, the intelligent motion guides Advanced Surface (standard) and Top Surface (optional item no .: 3584012) ensure optimum workpiece surfaces

- Easy transfer of the CAD data into the programming on the CNC by DXF-Reader (optional article no .: 3584014).

- 3D simulation on the PC for better control and optimization of the manufacturing process

Included

- Safety Integrated

- Remaining material detection and processing

- ShopMill machining step programming

- Manage network drive

- 3-D simulation

- Simultaneous recording

- PPU 290 with system software SW 28x

Control with control panel with PPU 290

- 15.6" color display

- 16: 9 format

- Capacitive display with multi-touch controller

- Intuitive multi-touch operation

- Softkey selection via touch function

- Proximity sensor / distance sensor for smart display control

- Die-cast magnesium panel front with scratch-resistant glass front

- No battery (permanent data caching by NV-RAM technology)

- No fan

- No hard disk

- Operation with work gloves possible

- Front interfaces: USB 2.0, RJ45 Ethernet, IP65 also with open protective flap

Functional safety also protects against high costs

- Avoidance of direct consequential costs of personal injury

- Avoidance of indirect consequential costs of injuries

- Increased productivity through increased machine availability: fewer unplanned downtime and smoother production

- Longer service life of the systems

- Improving global competitiveness by increasing the exportability of machinery

Equipment details:

Belt drive

- Offers a good combination of torque and speed that is suitable for a wide range of machining operations

- SK 40 / DIN 69871

- Spindle speeds 10,000 min¯¹

Inline spindle

- The direct connection between spindle and motor increases surface quality and thermal stability.

- Adapter SK 40 / DIN 69871

- Spindle speed 12,000 min¯¹

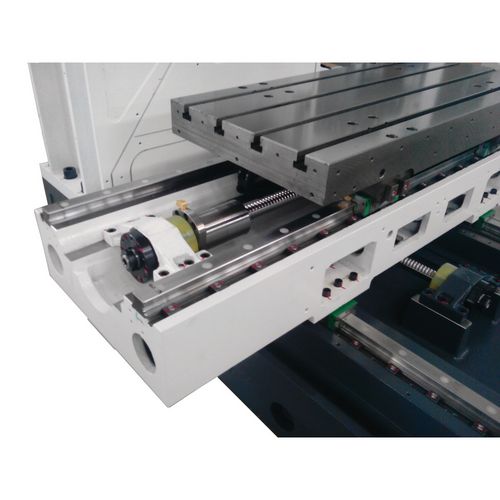

Linear guide

- Maximum static and dynamic rigidity

- High positioning accuracy

- Smooth, backlash-free movement

Milling table

- Solid, precise and large dimensions

- Clamping area 900 x 520 mm

- Accurately finish-machined surface

Cast body

- Quality cast in ribbed design

Machine feet

- Six pieces

- Optimal alignment of the machine

Cleaning gun

- Easy cleaning of the work area

Ball screws

- Accuracy class C3

- For high positioning and repeat accuracy

- Less wear

- Ball screw drive with servo motor

Chip flushing system

- Powerful chip flushing system for cleaning workspace and workpiece

Tool change system

- Double arm gripper with 30 tool places

- Max. tool length 300 mm

- Changes from tool to tool in 2 seconds

Oil separator / oil skimmer

- Oil skimmer reliably removes floating tramp oils and the finest swarf from cooling lubricants

Control cabinet

- Closed, clearly arranged control cabinet

- With SIEMENS servo drive

- Standard-compliant structure

Central lubrication system

- Significantly prevents wear, repair costs and unnecessary downtime

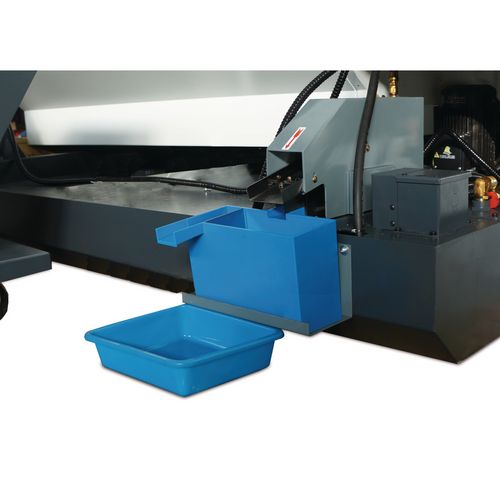

Chip conveyor

- Belt design

- For efficient chip removal

Cooling lubricant system

- Three coolant pumps with 1.27 kW each

- Tank capacity 370 liters

| Cooling lubricant system | |

|---|---|

| Number of coolant pumps | 3 St |

| Coolant pump(s) drive power | each 1.27 kW |

| Tank capacity | 370 l |

| Flow rate | 155 l/min |

| Dimensions and weights | |

|---|---|

| Length approx. | 3838 mm |

| Width/depth approx. | 2280 mm |

| Height approx. | 2260 mm |

| Weight approx. | 6250 kg |

| Drilling/milling output | |

|---|---|

| Max. size milling head | 63 mm |

| Max. size shaft milling cutter | 32 mm |

| Electrical connections | |

|---|---|

| Total rated value | 31 kVA |

| Electrical Data | |

|---|---|

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Fast motion speed | |

|---|---|

| X axis | 30000 mm/min |

| Y axis | 30000 mm/min |

| Z axis | 30000 mm/min |

| Feed force | |

|---|---|

| Feed force X-axis | 4.1 kN |

| Feed force Y-axis | 4.1 kN |

| Feed force Z-axis | 5.9 kN |

| Feed motor torque | |

|---|---|

| X axis continuous operation S1 | 11 Nm |

| Y axis continuous operation S1 | 11 Nm |

| Z axis continuous operation S1 | 16 Nm |

| Inline spindle | |

|---|---|

| Speeds | 12000 min¯¹ |

| Milling table horizontal | |

|---|---|

| Table length | 900 mm |

| Table width | 520 mm |

| Min. clearance vertical spindle - milling table | 100 mm |

| Max. clearance vertical spindle - milling table | 600 mm |

| T-groove size | 16 mm |

| T-groove number | 5 |

| T-groove spacing | 80 mm |

| Max. load bearing capacity | 450 kg |

| Pneumatic connection | |

|---|---|

| Operating pressure | 5 – 7 bar |

| Precision | |

|---|---|

| Repetition accuracy | ± 0.005 mm |

| Positioning accuracy | ± 0.005 mm |

| Travel | |

|---|---|

| X axis automatic | 800 mm |

| Y axis automatic | 500 mm |

| Z axis automatic | 500 mm |

| Turret | |

|---|---|

| Design | Double arm gripper |

| Number of tool slots | 30 Tools |

| Max. tool diameter adjacent slots free | 125 mm |

| Max. tool diameter | 75 mm |

| Max. tool length | 300 mm |

| Max. tool weight | 8 kg |

| Tool change time tool to tool (T to T) | 2 s |

| Vertical spindle | |

|---|---|

| Spindle chuck | SK 40 DIN 69871 |

| Speed range | 10000 min¯¹ |

| Explanation speed range | Please note that the maximum spindle speed must be reduced by approx. 20 % in continuous operation. |

| Drive motor output continuous operation S1 | 9 kW |

| Drive motor output S6-30 % operation | 21,2 kW |

| Torque drive motor continuous operation S1 | 57 Nm |

| Torque drive motor S6-30 % operation | 135 Nm |

| VPE | 1 |

Packaging unit: 1

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.

Accessories

Optional parts

Optional parts can not be retrofitted and are available only when ordering new machines.