| Cooling lubricant system | |

|---|---|

| Tank capacity | 380 l |

| Tank capacity external CTS unit | 165 l |

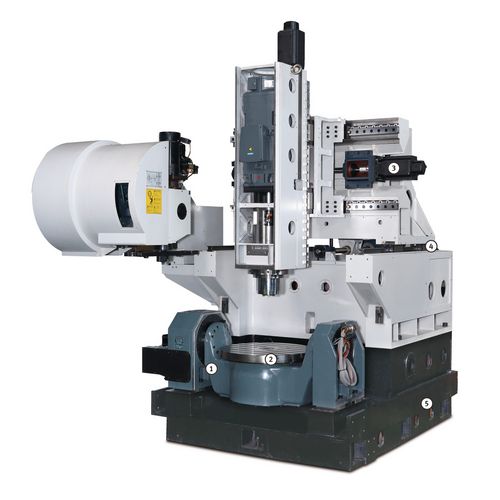

CNC milling machine

OPTImill FU 5-600 HSC 24

5-axis simultaneous machining center for powerful complete machining. With SIEMENS control 840D sl

Price upon request

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 3511386

Productdetails

- Heavy design

- High productivity

- Telescopic guideway cover

- Precision ground, preloaded high-performance ball screws for high rapid traverse speeds

- Spindle mounted in P5 precision bearings and permanently lubricated

- High-torque servo drives in all five axes

- Precision linear guide

- Heidenhain glass scales - additional measuring system ensures better accuracy

- High rapid traverse speed of up to 36 m/min

- C-axis with torque motor for maximum speed and lifecycle accuracy

- A-axis with worm gear for high torque during tilting processes

- The portable, electronic handwheel with acknowledgment button and emergency stop impact switch makes it much easier to run programs

- Tool changer double-arm gripper with 32 tool spaces in the standard scope of delivery (optionally available with 48 or 60 tool spaces)

- Coolant device with 380 liters coolant tank with chip flushing system and cleaning gun

- Automatic central lubrication

- RJ45 plug connection, USB and power connection 230 V

- Additional USB interface in the control panel

- Water circuit cooling unit for the main spindle and main spindle motor

- Chip conveyor in belt design ensures efficient chip removal

- Chip carriage

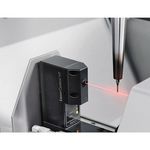

- Inside spindle cooling 20 bar with internal tank (suction is required)

- Heat exchanger

- EMC (electromagnetic compatibility)

- Two years Siemens repair service contract included

SINUMERIK 840D sl with OP 019 black multitouch operator panel

The right solution for every technological challenge

- The SINUMERIK 840D sl is rightly regarded as the benchmark in the CNC premium class. Maximum CNC performance as well as unrivaled flexibility and openness are the basis for almost every machine concept.

Multi-touch operation OP 019 black

- 18.5“ diagonal industrial display

- Maximum ease of use: Capacitive multi-touch technology (up to 5 contact points simultaneously)

- High resolution of 1,366 x 768 pixels in widescreen format

- Robust: No wear and tear on mechanical components thanks to multi-touch technology

- Scratch-resistant glass front

- Modern, intelligent design

- Can be operated with work gloves

SIEMENS SAFETY INTEGRATED - Setup with the door open

Functional safety also protects against high costs!

Machine and system safety is not only important because strict regulations have to be observed. If everything runs smoothly, you benefit from time savings in engineering, higher system availability and more investment security.

Modular and scalable

- In addition to scalable NCU performance, the SINUMERIK 840D sl also offers a high degree of modularity in the operator components. With a flexible operating concept - e.g. B. the combination of any operator panels with the NCU - the SINUMERIK 840D sl adapts ideally to the operating philosophy of modern premium machine concepts.

Benchmark in Open Architecture

- The system openness of the SINUMERIK 840D sl is unique. In this way, the CNC can be optimally adapted to the technology of the machine and has a high degree of freedom in production automation.

Complete package

- SINUMERIK Safety Integrated safety functions

- Residual material detection and processing

- ShopMill machining step programming

- MDynamics 5-axis

- Manage network drive

- 3-D simulation

- Advanced Surface

- Spline interpolation

- Transmit and lateral surface transformation

- Measuring cycles

- Simultaneous recording

- HMI user memory on CF card

- 3-D tool radius compensation

- Kinematic measuring cycle CYCLE996

SIEMENS NCU 730.3

- Up to 31 axes

- Cycle time 0.3 ms

- Up to 1,500 tools

- Collision avoidance possible

Extension of the SIEMENS repair service contract (RSV)

With the SIEMENS Repair Service Contract (RSV) you protect your ma machine for a further 12, 24 or 36 months (only to be purchased within the two-year Siemens warranty)

- 12 months; Article No. 3589035

- 24 months; Article No. 3589036

- 36 months; Article No. 3589037

Equipment details

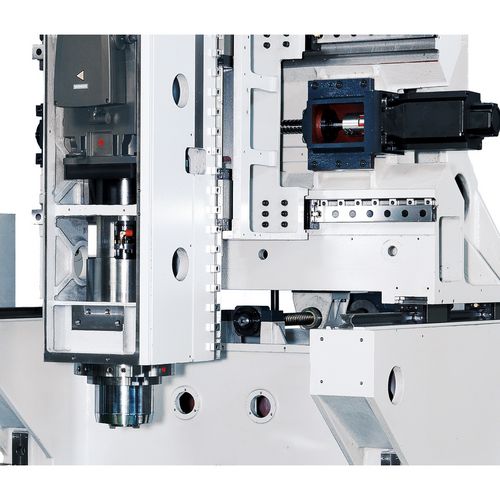

Main spindle and motor

- Water-cooled

Central drive

- X-axis

Spindle

- Inline spindle with a speed of 15,000 rpm

or

- High-frequency spindle (built-in spindle) from Kessler with a speed of 24,000 rpm

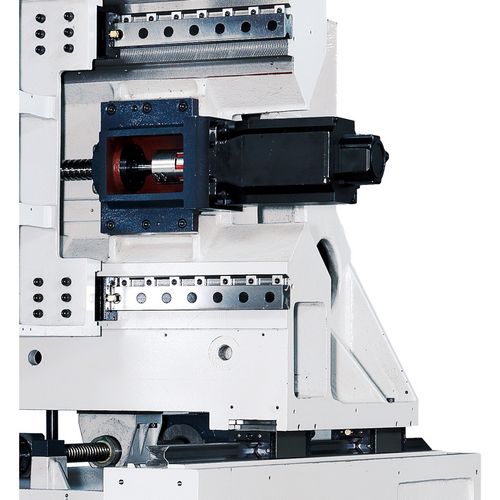

Swivel and rotary table

- By L.C.M Italy

- Perfect geometric and functional coordination

Chip removal

- Machine designed for optimal chip removal

Base

- Strongly ribbed, torsion-free machine base made of quality cast

Swivel and rotary table

- Rotation speed max. 90 min¯¹

- Tilting speed max. 16.6 min¯¹

- 3 hydraulic and 1 pneumatic connection (without valves)

- High-precision A-axis & C-axis

- Maximum table load 600 kg

Feed axes

- Directly driven

- Rapid traverse X, Y, Z axis 36 m/min

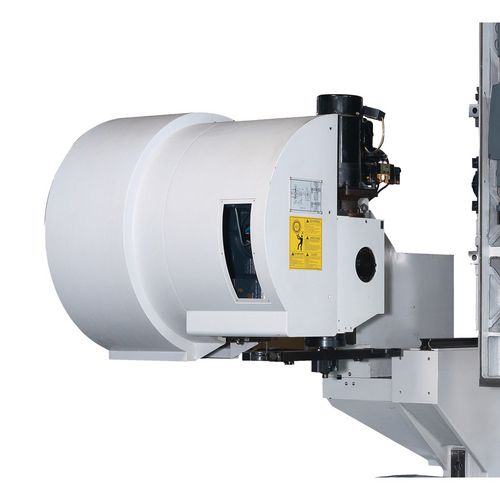

Tool changer

- Double arm gripper

- Drum magazine

- 32 tool places

- Optionally with 48 or 60 tool places

Grease lubrication

- Reduces the wear

- High load-bearing capacity

- Excellent lubricating film

- Low maintenance requirement

- Good adhesion properties

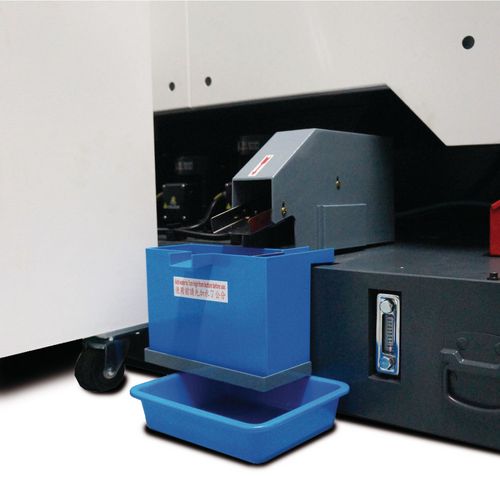

Oil separator / oil skimmer

- Oil skimmer reliably removes floating tramp oils and the finest swarf from cooling lubricants

Guides

- High-precision roller guides in all three axes

- Front linear guides contain additional guide carriages to ensure dynamic stability.

Control

- New generation of control panels with new options for machine operation

- Modern multi-touch screen surface

Chip conveyor

- Belt design

- For efficient chip removal

Water circulation unit

- Cooling of the main spindle and the main spindle motor

| Dimensions and weights | |

|---|---|

| Length approx. | 3015 mm |

| Width/depth approx. | 4440 mm |

| Height approx. | 3000 mm |

| Weight approx. | 9150 kg |

| Electrical connections | |

|---|---|

| Total rated value | 77 kVA |

| Electrical Data | |

|---|---|

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Fast motion speed | |

|---|---|

| X axis | 36000 mm/min |

| Y axis | 36000 mm/min |

| Z axis | 36000 mm/min |

| Feed force | |

|---|---|

| Feed force X-axis | 10 kN |

| Feed force Y-axis | 10 kN |

| Feed force Z-axis | 10 kN |

| Feed motor torque | |

|---|---|

| X axis continuous operation S1 | 20 Nm |

| Y axis continuous operation S1 | 20 Nm |

| Z axis continuous operation S1 | 20 Nm |

| Feed speed | |

|---|---|

| Acceleration X, Y, Z axis | 7 m/s² |

| Milling table horizontal | |

|---|---|

| T-groove size | 14 mm |

| T-groove number | 7 |

| T-groove spacing | 75 mm |

| Max. load bearing capacity | 600 kg |

| Pneumatic connection | |

|---|---|

| Operating pressure | 6 bar |

| Precision | |

|---|---|

| Repetition accuracy | ± 0,004 mm |

| Positioning accuracy | ± 0,008 mm |

| Pump | |

|---|---|

| Pump motor chip flushing | 0,85 kW |

| Pump motor chip flushing conveying rate | 150 l/min |

| Pump motor front/left chip flushing | 1.08 kW |

| Pump motor front/left chip flushing delivery rate | 150 l/min |

| Pump motor cleaning gun | 0.53 kW |

| Pump motor cleaning gun delivery rate | 58 l/min |

| Rotary axis | |

|---|---|

| Rotary axis max. permissible torque (S1) | 393 Nm |

| Rotary axis max. permissible torque (S6) | 707 Nm |

| Swivel axis | ± 120 ° |

| Rotation axis | 360 ° |

| Rotary table diameter | 600 mm |

| Max. speed A axis | 16.6 min¯¹ |

| Max. speed C axis | 90 min¯¹ |

| Tilting and rotating table | |

|---|---|

| Hydraulic clamping torque swivel axis C (at 50 bar hydraulic pressure) | 1200 Nm |

| Hydraulic clamping torque swivel axis A (at 50 bar hydraulic pressure) | 2900 Nm |

| Travel | |

|---|---|

| X axis automatic | 600 mm |

| Y axis automatic | 600 mm |

| Z axis automatic | 500 mm |

| Turret | |

|---|---|

| Number of tool slots | 32 Tools |

| Max. tool diameter adjacent slots free | 120 mm |

| Max. tool diameter | 78 mm |

| Max. tool length | 300 mm |

| Max. tool weight | 7 kg |

| Tool change time chip to chip (C to C) | 9.33 s |

| Vertical spindle | |

|---|---|

| Spindle chuck | HSK 63 DIN 69893 |

| Speed range | 24000 min¯¹ |

| Drive motor output continuous operation S1 | 25 kW |

| Drive motor output S6-30 % operation | 35 kW |

| Torque drive motor continuous operation S1 | 32 Nm |

| Torque drive motor S6-30 % operation | 39 Nm |

| VPE | 1 |

Packaging unit: 1

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.

Optional parts

Optional parts can not be retrofitted and are available only when ordering new machines.