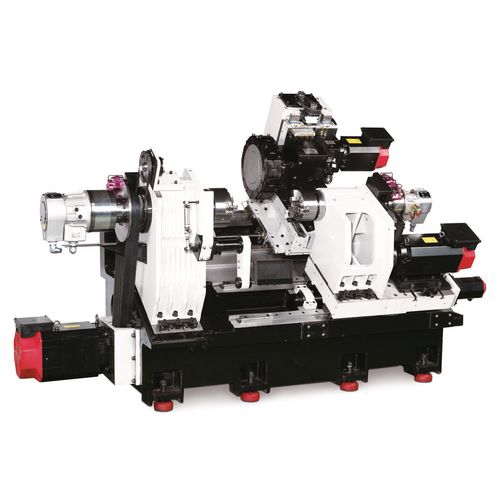

- Heavy duty design

- Compact design

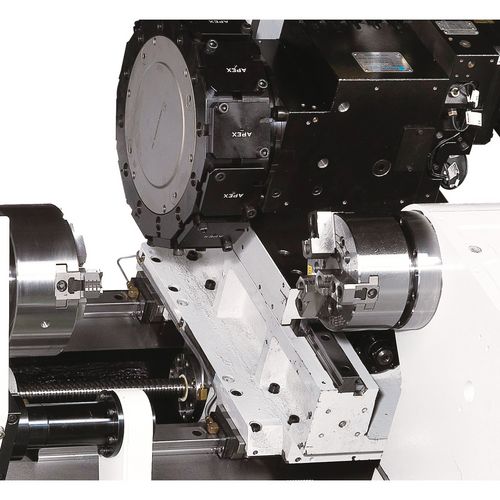

- Slanted bed design 30° for particularly large machining diameters

- Easy chip discharge into the chip tray

- Dimensionally stable linear guides - ensure a long service life through maximum static and dynamic rigidity.

- Hardened and ground ball screws

- SIEMENS servomotors in all axes

- All servomotors with integrated encoder for highest accuracy

- Portable electronic handwheel facilitates program retraction considerably

- Chip conveyor

- Halogen work lamp

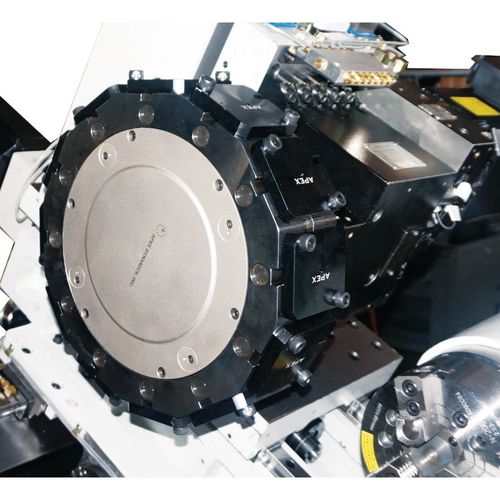

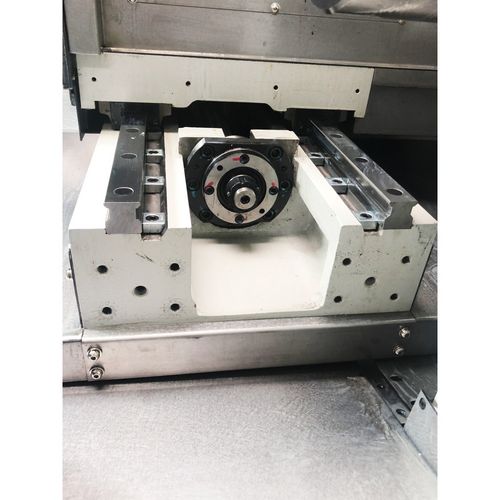

- C-axis with brake system APEX PT16-16-RB-330 and 12 tools VDI 30

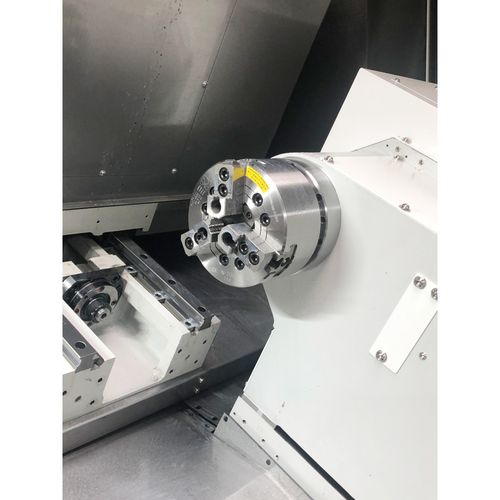

- Hydraulic three-jaw chuck Ø 200 mm and on the counter spindle 150 mm

- Coolant system

- Foot switch

- Automatic lubrication system

- Hydraulic unit

- Cabinet heat exchanger

- Bar loader interface

- EMC (Electromagnetic compatibility)

| Control |

|---|

| Type of Control | Sinumerik 828D |

| Sinumerik 828D system software (factory option) | SW 28x |

| CNC memory | 8 MB |

| Look Ahead | 150 |

| Set change time | 1 ms |

| Number of tools | 512 |

| Cooling lubricant system |

|---|

| Coolant pump output | 530 W |

| Central lubrication system output | 30 W |

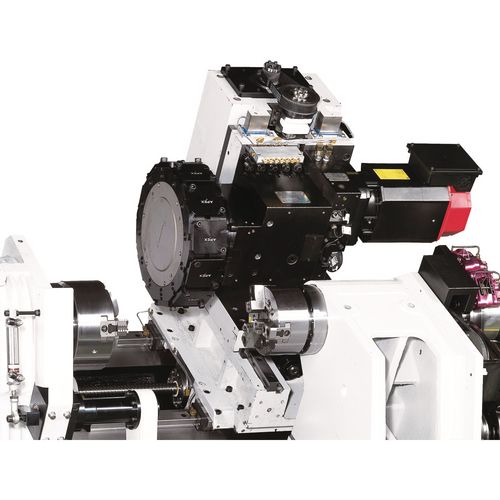

| Counter spindle |

|---|

| Output drive motor continuous operation S1 | 7,5 kW |

| Torque drive motor | 50 nm |

| Output drive motor S6-30% operation | 11 kW |

| Torque drive motor S6-30% operation | 112 nm |

| Spindle taper | DIN ISO 702-1 No. 5 |

| Sub spindle bore | 52 mm |

| Chuck passage | 45 mm |

| Hydraulic lathe chuck | 150 mm |

| Speed range | 0 – 5000 min¯¹ |

| Dimensions and weights |

|---|

| Max. length | 4485 mm |

| Length approx. | 4020 mm |

| Width/depth approx. | 3135 mm |

| Height approx. | 1950 mm |

| Weight approx. | 6000 kg |

| Electrical connections |

|---|

| Total rated value | 20 kVA |

| Electrical Data |

|---|

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Feed force |

|---|

| Feed force X-axis | 6.9 kN |

| Feed force Y-axis | 6.2 kN |

| Feed force Z-axis | 10 kN |

| Feed speed |

|---|

| X axis | 24000 mm/min |

| Y axis (factory option) | 6000 mm/min |

| Z axis | 24000 mm/min |

| Hydraulic system |

|---|

| Motor output | 2,2 kW |

| Machine data |

|---|

| Chuck passage diameter | 65 mm |

| Angled bed | 30 ° |

| Motor torque |

|---|

| X axis | 11 Nm |

| Y axis | 6 Nm |

| Z axis | 16 Nm |

| Precision |

|---|

| Repetition accuracy | ± 0.005 mm |

| Positioning accuracy | ± 0.005 mm |

| Product information EU 2023/2854 |

|---|

| Type of the generated data | Usage data |

| Format of the generated data | Common, machine-readable formats such as JSON |

| Amount of data | Up to 5 MB |

| Continuous data generation in real time | Yes |

| Data storage location | On the device |

| Data access | Via physical interfaces |

| Further information | In the operating instructions or at info@stuermer-maschinen.de |

| Spindle |

|---|

| Spindle chuck | DIN ISO 702-1 No. 6 |

| Spindle bore with hydraulic chuck | 200 mm |

| Main spindle bore | 75 mm |

| Travel |

|---|

| Travel X axis | 215 mm |

| Travel Z axis | 1020 mm |

| Y axis travel (factory option) | 100 (+/- 50) mm |

| Z2 axis | 1020 mm |

| Turret |

|---|

| Type | hydraulic VDI30 DIN 5480 |

| Number of tool slots | 12 Tools |

| Drive motor output | 3.75 kW |

| Max. chuck height, width square | 25 x 25 mm |

| Max. chuck diameter drilling rod | 40 mm |

| Max. permissible speed at tool coupling | 6000 min¯¹ |

| Vertical spindle |

|---|

| Drive motor output continuous operation S1 | 11 kW |

| Drive motor output S6-30 % operation | 15 kW |

| Drive motor torque | 98.7 Nm |

| Drive motor torque S6-30 % operation | 199.2 Nm |

| Work areas |

|---|

| Turning length | 1020 mm |

| Center height | 325 mm |

| Swing diameter above machine bed | 650 mm |

| Swing diameter above planing slide | 380 mm |

Unit: pc(s).

Packaging unit: 1

Optimum Maschinen Germany GmbH

Dr.-Robert-Pfleger-Str. 26

Deutschland / Germany

96103 Hallstadt

info@optimum-maschinen.de