| Data sheets | |

|---|---|

| Sicherheits- und Warnhinweise | |

| Safety and warning notices |

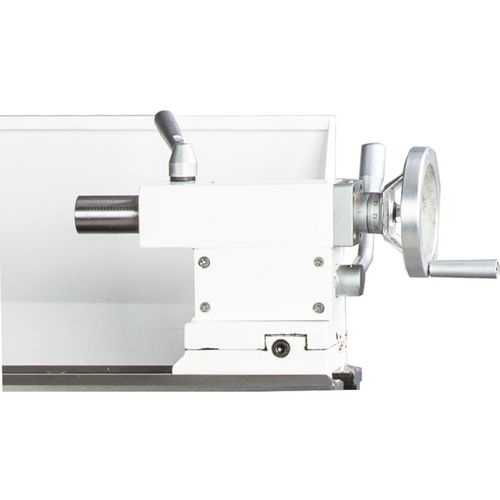

Center lathe

OPTIturn TU 2506 (400 V)

Center lathe with feed gear for the demanding user

2.366,91 EUR incl. 19% Tax / pc(s).

Promotional price *

1.899,00 EUR excl. Tax / pc(s).2.259,81 EUR incl. 19% Tax / pc(s).

Prices are recommended retail prices. Retailer prices may vary.

* Promotional price valid until 28.02.2026 in Germany.

Art.-No. 3425003

Productdetails

- Precisely manufactured

- Powerful, maintenance-free engine

- Hardened and ground Z-axis guideway

- Guaranteed concentricity of the spindle nose ≤ 0.009 mm

- Concentricity on the lathe chuck ≤ 0.04 mm

- Lead screw for thread cutting or automatic longitudinal turning

- Leadscrew stored in two sintered bearings

- All guides can be adjusted by wedge strips

- Right / left rotation in the control panel switchable

- Rolled trapezoid spindles

- Thrust bearing

- Tapered roller bearings in P5 quality

- Hardened main spindle mounted in adjustable precision tapered roller bearings

- Hardened spindle nose with Ø 26 mm spindle bore

- Handwheels on the carriage with adjustable fine scale 0.04 / 0.01 mm

- Upper slide on cross slide slidable

- Chip protection on the upper slide

- Heavily ribbed prism bed made of gray cast iron, inductively hardened and precision ground

- Tailstock for taper turning ± 5 mm adjustable

- Tailstock quill and handwheel with adjustable fine scale 0.02 mm

- Quick, easy and tool-free adjustment of the tailstock by a clamping lever

- Emergency stop impact switch

- Quadruple tool holder

- 3-jaw lathe chuck in the standard scope of delivery

- Change gear set in the standard scope of delivery for thread cutting

- Fully equipped, allowing the user to be productive immediately after commissioning

- TU 2506VB: Speed change easily adjustable via potentiometer

You will receive the 3-year Stürmer warranty for this item when you register online.

| Dimensions and weights | |

|---|---|

| Length approx. | 1250 mm |

| Width/depth approx. | 585 mm |

| Height approx. | 475 mm |

| Weight approx. | 138 kg |

| Electrical Data | |

|---|---|

| Drive motor output | 0,75 kW |

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Feed | |

|---|---|

| Longitudinal feed range | 0,07 – 0,4 mm/rev |

| Number of longitudinal feeds | 6 |

| Pitches | |

|---|---|

| Metric pitch | 0,2 – 4 mm/rev |

| Number of metric pitches | 21 |

| Imperial pitch | 56 – 8 Gg/1" |

| Number of imperial pitches | 21 |

| Speed range | |

|---|---|

| Number of gears | 6 Steps |

| Speed range | 125 – 2000 min¯¹ |

| Spindle | |

|---|---|

| Spindle chuck | short taper |

| Spindle bore/rod passage diameter | 26 mm |

| Tool holder max. chuck height | 12 mm |

| Spindle cone | MT 4 |

| Tailstock | |

|---|---|

| Chuck | MK 2 |

| Quill stroke | 65 mm |

| Quill diameter | 30 mm |

| Travel | |

|---|---|

| Travel upper slide | 70 mm |

| Travel cross slide | 110 mm |

| Travel carriage saddle | 550 mm |

| Work areas | |

|---|---|

| Center height | 125 mm |

| Distance between center | 550 mm |

| Swing diameter above machine bed | 246 mm |

| Swing diameter above planing slide | 149 mm |

| Bed width | 134 mm |

| VPE | 1 |

Packaging unit: 1

- Three-jaw lathe chuck Ø 125 mm, centrically exciting

- Fixed centering point MK 2 and MK 4

- Quadruple tool holder 12 mm

- HSS lathe tool

- Bulkhead

- Chip pan

- Change gear set

- Operating tool

Dr.-Robert-Pfleger-Str. 26

Deutschland / Germany

96103 Hallstadt

info@optimum-maschinen.de

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.