| Data sheets | |

|---|---|

| Sicherheits- und Warnhinweise | |

| Safety and warning notices |

CNC lathe

OPTIturn S 600 MSY

OPTIMUM PREMIUM CNC slant bed lathe with counter spindle and Y/C axis, characterized by high speed, performance, precision and durability

Price upon request

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 3515187

Productdetails

- Heavy-duty design

- Compact design

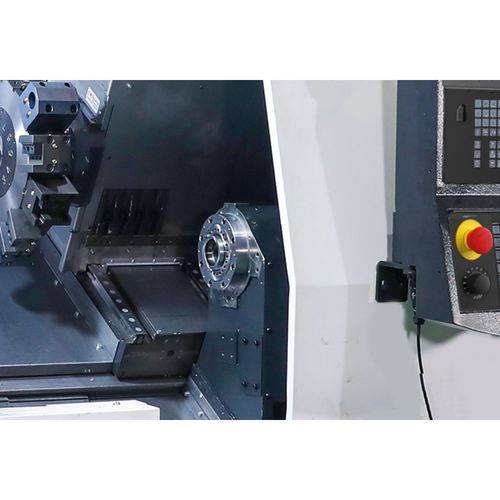

- Renishaw measuring arm for manual tool measurement

- Directly mounted main spindle encoder for higher accuracy

- Ball screw with improved accuracy, rigidity and heat resistance

- Siemens servo motors in all axes

- All servo motors with integrated encoder for maximum accuracy

- The motor is located on the side of the machine and prevents heat transfer and vibrations caused by the motor

- Inclined bed design 30° for particularly large machining diameters

- Better unhindered chip flow into the chip tray

- Hydraulic three-jaw lathe chuck Ø 250 mm for the main spindle and Ø 150 mm for the counter spindle

- Hardened and precision-ground ball screws for high rapid traverse speeds in all axes

- Dimensionally stable linear guides ensure a long service life thanks to maximum static and dynamic rigidity

- Device for manual tool measurement

- Heat exchanger

- Portable, electronic handwheel with enabling switch and emergency stop switch makes it much easier to run in programs

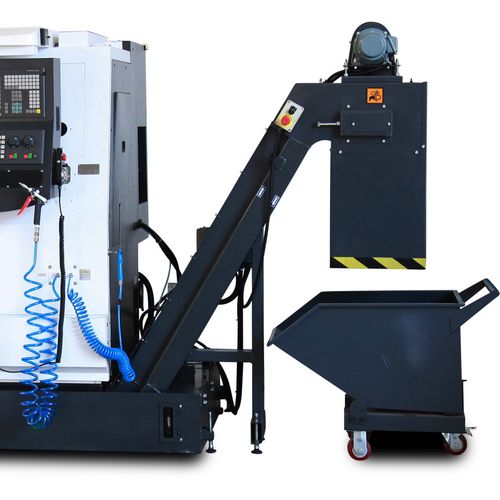

- Belt-type chip conveyor ensures efficient chip removal

- Work light for complete illumination of the work area

- Coolant device with cleaning gun

- RJ45 , power interface

- EMC (electromagnetic compatibility)

- Additional package SIEMENS material defect liability and free online/on-site service OSS Plus

- 1 year maintenance contract Basic included in D/A/CH

SINUMERIK 828D PPU271.5

Compact revolution. Digitally transformed, innovatively designed, enhanced performance.

Digital twin

Create / Run MyVirtual Machine now available for 828D.

- Minimize setup and run-in time on the real machine.

- Precise simulation reduces the risk of collision and speeds up part program optimization.

Higher performance

- CPU performance improved by >40

- 40% shorter program buffer and processing time

- 25 % higher simulation efficiency

- 50 % faster HMI switchover timeImproved

- efficiency, shorter waiting times and smooth operation

Modern panel design

Innovative 16:10-inch panel with modern design. SINUMERIK 828D MCP with laser-engraved characters, mechanical keys, override key life increased by 400%

- Clearer display and improved user-friendliness

- Excellent haptics and wear-resistant buttons, greater robustness and longer service life

Sustainability & security

New Ctrl-E Advanced Analysis function

Maintenance-free (no fan, no battery)

Security functions: Security archive, user administration

- Simple transparency of energy consumption

- Protection of customer know-how against manipulation and piracy

Safety Integrated

Functional safety also protects against high costs!

Machine and system safety is not only important because strict regulations must be observed. When everything runs safely, you benefit from time savings in engineering, higher system availability and greater investment security.

Control system

- 10.4" color display

- 4:3 format

- User-friendly SINUMERIK Operate software

System software PPU 271 SW 24

- 3 MB CNC memory

- 3 ms block change time

- 50 Look Ahead

- 128 tools

Complete package

- Safety Integrated

- Residual material detection and machining

- ShopMill work step programming

- Manage network drive

- 3-D simulation

- Co-drawing

Additional package SIEMENS OSS Plus

- 12 months; article no. 3589020

- 24 months; article no. 3589021

- 36 months; article no. 3589022

Information on this additional package and conditions for claiming under: Material Defects Liability and On-Site Service - SiePortal - Siemens WWF

| C axis (factory option) | |

|---|---|

| Angular accuracy | 51 " |

| Repeat accuracy | 20 " |

| Cooling lubricant system | |

|---|---|

| Coolant pump output | 0.7 kW |

| Tank capacity | 240 l |

| Counter spindle | |

|---|---|

| Output drive motor continuous operation S1 | 5.5 kW |

| Torque drive motor | 43 Nm |

| Output drive motor S6-30% operation | 7.5 kW |

| Torque drive motor S6-30% operation | 79 Nm |

| Spindle taper | DIN ISO 702-1 No. 5 |

| Chuck passage | 44 mm |

| Hydraulic lathe chuck | 150 mm |

| Dimensions and weights | |

|---|---|

| Length approx. | 4490 mm |

| Width/depth approx. | 1880 mm |

| Height approx. | 1900 mm |

| Weight approx. | 4500 kg |

| Electrical connections | |

|---|---|

| Total rated value | 45 kVA |

| Electrical Data | |

|---|---|

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Fast motion speed | |

|---|---|

| X-axis | 24 m/min |

| Y-axis | 10 m/min |

| Y-axis | 30 m/min |

| Z2-xis | 30 m/min |

| Feed force | |

|---|---|

| Feed force X-axis | 8.4 kN |

| Feed force Y-axis | 18 kN |

| Feed force Z-axis | 6.7 kN |

| Hydraulic system | |

|---|---|

| Motor output | 2.2 kW |

| Tank capacity | 36 l |

| Machine data | |

|---|---|

| Chuck passage diameter | 74 mm |

| Angled bed | 30 ° |

| Chuck diameter | 51 mm |

| Motor torque | |

|---|---|

| X axis | 11 Nm |

| Y axis | 12 Nm |

| Z axis | 11 Nm |

| Product information EU 2023/2854 | |

|---|---|

| Type of the generated data | Usage data |

| Format of the generated data | Common, machine-readable formats such as JSON |

| Amount of data | Up to 5 MB |

| Continuous data generation in real time | Yes |

| Data storage location | On the device |

| Data access | Via physical interfaces |

| Further information | In the operating instructions or at info@stuermer-maschinen.de |

| Speed range | |

|---|---|

| Speed range | 30 - 3500 min¯¹ |

| Spindle | |

|---|---|

| Spindle chuck | DIN ISO 702-1 No. 6 |

| Spindle bore/rod passage diameter | 86 mm |

| Spindle bore with hydraulic chuck | 250 mm |

| Positioning accuracy | ± 0,005 mm |

| Spindle bore | 62 mm |

| Explanation Feed passage | with Ø 200 mm chuck |

| Spindle speed | 30 4500 min¯¹ |

| Spindle holder | A 2-6 |

| Spindle bore | 102 mm |

| Feed passage | 90 mm |

| Explanation of feed passage | with Ø 300 mm chuck |

| Spindle holder | A 2-8 |

| Spindle speed | 30 3000 min¯¹ |

| Spindle bore | 116 mm |

| Feed passage | 105 mm |

| Explanation of feed passage | with Ø 300 mm chuck |

| Spindle holder | A 2-8 |

| Spindle speeds | 30 2500 min¯¹ |

| Travel | |

|---|---|

| Travel X axis | 220 mm |

| Travel Z axis | 700 mm |

| Y axis | 50 mm |

| Z2 axis | 600 mm |

| Turret | |

|---|---|

| Type | BMT55 |

| Number of tool slots | 12 |

| Drive motor output | 4.8 kW |

| Max. permissible speed at tool coupling | 4000 min¯¹ |

| Max. tool torque | 20 Nm |

| Vertical spindle | |

|---|---|

| Drive motor output continuous operation S1 | 15 kW |

| Drive motor output S6-30 % operation | 19.5 kW |

| Drive motor torque | 268 Nm |

| Drive motor torque S6-30 % operation | 349 Nm |

| Work areas | |

|---|---|

| Lathe chuck diameter | 300 mm |

| Turning length | 600 mm |

| Swing diameter above machine bed | 660 mm |

| Swing diameter above planing slide | 480 mm |

| VPE | 1 |

Packaging unit: 1

- Axial tool holder driven tools

- 2 radial tool holders for driven tools

- 3 drilling tool holders

- 5 OD tool holders

- Face tool holder

- Round holder Ø 20 mm

- Round holder Ø 25 mm

- Round holder Ø 32 mm

Dr.-Robert-Pfleger-Str. 26

Deutschland / Germany

96103 Hallstadt

info@optimum-maschinen.de

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.

Accessories

Optional parts

Optional parts can not be retrofitted and are available only when ordering new machines.