| C axis (factory option) | |

|---|---|

| Drive motor output | 5 kW |

| Torque | 20 Nm |

| Speed range | 4500 min¯¹ |

CNC lathe with cycle control

OPTIturn L 440

The OPTIMUM PREMIUM high-performance CNC lathe with cycle control. SIEMENS CONTROL SINUMERIK 828D BASIC

Price upon request

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 3514410

Productdetails

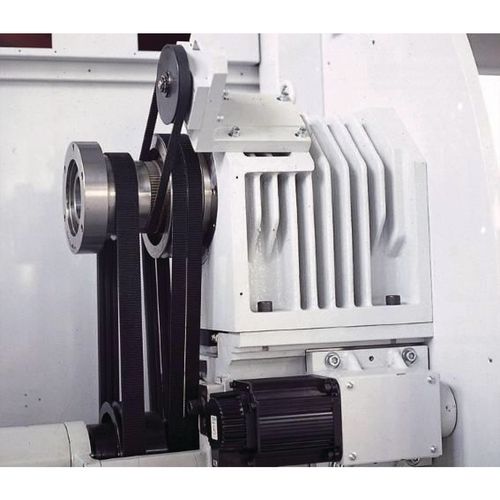

- High-precision machine with the latest SIEMENS control and SIEMENS servo-drives

- Compact headstock design

- High-speed spindle 4,500 rpm with high-precision and large-sized tapered roller bearings

- Changing between the two gear stages is done pneumatically via a pneumatic cylinder

- Construction of the headstock guarantees a minimum noise level

- Wide machine bed with double rectangular guideways, also for roughing operations

- Hardened and ground bed lanes

- Tailstock generously dimensioned and easy to position with a quick-release tensioner

- Two front, separately movable sliding doors with integrated viewing windows

- Microswitch prevents start-up with the door not fully closed

- RJ45 plug connection, USB and power connection 230 V

- Mobile control panel

- Two electronic handwheels for manual operation X and Z axis

- Automatic headstock lubrication

- Automatic lubrication of longitudinal and cross slides

- Halogen work lamp

- Closed Control cabinet with integrated heat exchanger, ensures optimum temperature even at high outside temperatures and prevents the ingress of dirt particles.

- Hard and soft block jaws

- Tailstock end cover

- Six machine feet

- Heat Exchanger

- EMC (Electromagnetic Compatibility)

| Control | |

|---|---|

| Type of Control | Sinumerik 828D PPU 271 |

| Sinumerik 828D system software (factory option) | SW 24 |

| CNC memory | 3 MB |

| Look Ahead | 50 |

| Set change time | 3 ms |

| Number of tools | 128 |

| Cooling lubricant system | |

|---|---|

| Coolant pump output | 375 W |

| Tank capacity | 170 l |

| Dimensions and weights | |

|---|---|

| Length approx. | 3030 mm |

| Width/depth approx. | 1952 mm |

| Height approx. | 2025 mm |

| Weight approx. | 3000 kg |

| Electrical connections | |

|---|---|

| Total rated value | 25 kVA |

| Electrical Data | |

|---|---|

| Drive motor output | 11 kW |

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Feed force | |

|---|---|

| Feed force X-axis | 7,5 kN |

| Feed force Z-axis | 10 kN |

| Feed speed | |

|---|---|

| X axis | 15000 mm/min |

| Z axis | 15000 mm/min |

| Hydraulic system | |

|---|---|

| Motor output | 0,75 kW |

| Tank capacity | 50 l |

| Machine data | |

|---|---|

| Chuck passage diameter | 52 mm |

| Motor torque | |

|---|---|

| X axis | 6 Nm |

| Z axis | 16 Nm |

| Motor(s) | |

|---|---|

| Drive motor torque | 70 Nm |

| Precision | |

|---|---|

| Repetition accuracy | ± 0.005 mm |

| Positioning accuracy | ± 0.005 mm |

| Product information EU 2023/2854 | |

|---|---|

| Type of the generated data | Usage data |

| Format of the generated data | Common, machine-readable formats such as JSON |

| Amount of data | Up to 5 MB |

| Continuous data generation in real time | Yes |

| Data storage location | On the device |

| Data access | Via physical interfaces |

| Further information | In the operating instructions or at info@stuermer-maschinen.de |

| Spindle | |

|---|---|

| Spindle chuck | DIN ISO 702-1 No. 6 |

| Spindle bore/rod passage diameter | 65 mm |

| Tailstock | |

|---|---|

| Chuck | MT 4 |

| Quill stroke | 150 mm |

| Quill diameter | 65 mm |

| Travel | |

|---|---|

| Travel X axis | 260 mm |

| Travel Z axis | 1150 mm |

| Turret | |

|---|---|

| Type | hydraulic; LS 160 VDI 40 |

| Number of tool slots | 8 St |

| Max. chuck height, width square | 25 x 25 mm |

| Max. chuck diameter drilling rod | 32 mm |

| Vertical spindle | |

|---|---|

| Drive motor output continuous operation S1 | 11 kW |

| Drive motor output S6-30 % operation | 23 kW |

| Drive motor torque | 70 Nm |

| Drive motor torque S6-30 % operation | 148 Nm |

| Work areas | |

|---|---|

| Lathe chuck diameter | 200 mm |

| Lathe chuck actuation of clamping movement | hydraulic |

| Center height | 235 mm |

| Distance between center | 1000 mm |

| Swing diameter above machine bed | 475 mm |

| Swing diameter in bed bridge | 710 mm |

| Swing diameter above planing slide | 240 mm |

| VPE | 1 |

| Sicherheits- und Warnhinweise | |

| Safety and warning notices |

Packaging unit: 1

- EMC

- Portable electronic handwheel

- Hydraulic tool turret LS160 VDI40

- Hydraulic 3-jaw chuck Ø 200 mm

- Hard and soft block cheeks

- heat exchangers

- Tailstock end cover

- 6 pcs. machine feet

- Coolant system

INFORMATION

Lifting device 3514301

To unload the machine, a lifting device is needed

Dr.-Robert-Pfleger-Str. 26

Deutschland / Germany

96103 Hallstadt

info@optimum-maschinen.de

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.

Accessories

Optional parts

Optional parts can not be retrofitted and are available only when ordering new machines.