| Control | |

|---|---|

| Type | Sinumerik 828D |

| System software | SW 28x |

| CNC memory | 8 MB |

| Set change time | 1 ms |

| Look Ahead | 150 |

| Number of tools | 512 |

CNC milling machine

OPTImill FU 3/3+2

3 + 2 - axis machining center for powerful complete machining

Price upon request

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 3511370

Productdetails

- Siemens Sinumerik 828D control with 15.6 inch touch display

- Heavy design

- High productivity

- The CAM software and the milling strategies correspond to normal 3-axis programming

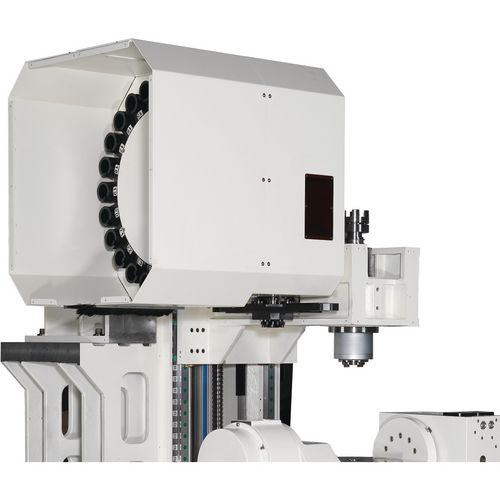

- Side-mounted tool changer - double-arm gripper with 24 tool positions

- Inline spindle with a maximum spindle speed of 15,000 rpm. The direct connection between the spindle and the motor increases the surface quality and thermal stability

- The portable, electronic handwheel with acknowledgment button and emergency stop push button makes it much easier to run programs

- Coolant system with 250 liters Coolant tank with chip flushing system and cleaning gun

- Automatic central lubrication

- Chip conveyor in belt design ensures efficient chip removal

- Chip carriage

- High-performance oil cooler for spindle cooling and ball screw drive

- Internal spindle cooling 20 bar internal (suction is required)

- EMC (electromagnetic compatibility) and safety module from Siemens

- Enclosed control cabinet with integrated heat exchanger ensures optimum temperature and prevents the penetration of dirt particles

- Automatic central lubrication

- Machine lamp for complete illumination of the work area

- RJ45 plug connection, USB connection and 230 V power connection

- Ethernet

SINUMERIK 828D - The power pack in the compact class of CNC controls

Increased productivity and precision in production

Robust hardware architecture and intelligent control algorithms as well as drive and motor technology in a class of its own ensure a maximum of dynamics and accuracy during processing.

Extended software-controlled compensation functions ensure additional quality in surface machining and high availability of the machine tool.

With SINUMERIK Operate, all machining technologies, from standard to complex, can be operated intuitively and with a uniform “look and feel”.

ADVANCED SURFACE

- Thanks to the new ADVANCED SURFACE motion control, it can also be used for tool and mold making.

TOP SURFACE

- With TOP SURFACE, Siemens is showing a further development in surface quality in mold making(optional article no. 3584012).

- The function optimizes the CAD/CAM-CNC data, which reduces the dependence of the manufacturing quality on the CAD/CAM calculation tolerance and improves the surface quality and dimensional accuracy.

DXF-READER

- Faster from drawing to component. Easy transfer of the CAD data into the programming by DXF-READER (optional article no. 3584014).

SIEMENS SAFETY INTEGRATED - Setup with opened door

Functional safety also protects from high costs!

Machine and system safety is not only important because strict regulations have to be observed. If everything runs safely, you benefit from time savings in engineering, higher system availability and more security of investment.

TOTAL PACKAGE

- Safety Integrated

- Residual material detection and processing

- ShopMill work step programming

- Managed network drive

- 3-D simulation

- Simultaneous recording

- System software SW 28x

Multi-touch operation with PPU 290

The 15.6" panel is robust even in harsh environments. The SINUMERIK Operate user interface is optimized for touch-sensitive operation.

User-friendly

- Capacitive 15.6" color display in 16:9 format

- Configurable side screen

- Intuitive multi-touch operation

- Full-fledged QWERTY keyboard

- Softkey selection via touch function

- Simple data transfer through IP65-protected front interfaces (USB 2.0, RJ45 Ethernet)

- Proximity/distance sensor for smart display control

Robust and maintenance-free

- Panel front made of die-cast magnesium with scratch-resistant glass front

- Can be operated with work gloves

- NV-RAM storage technology without backup battery

- Fanless and hard drive-free layout

Extended warranty

With the extended warranty you protect your new machine against warranty damage for a further 12 or 36 months (only to be bought with purchase of machine).

- 12 months; Article No. 3589020

- 36 months; Article No. 3589022

Equipment details

Inline spindle

- The direct connection between spindle and motor increase the surface quality and thermal stability

- Adapter SK 40 / DIN 69871

- Spindle speed 15,000 rpm

Guides

- High-precision linear roller guides for the axes ensure high rigidity and accuracy

- Fast acceleration and deceleration speeds

Chip removal

- Machine designed for optimal chip removal

Base

- Strongly ribbed, torsion-free machine base made of quality cast

Precision ball screw drives

- With pre-tensioned double nut that enables a high tolerance and low clearance

- Cooled rotating spindle

Large working area

- For an enormous variety of uses of the machine

- Distance spindle to table 100 - 500 mm

Control

- Can be swiveled and rotated

- With signal light

Tool changer

- Double arm gripper

- Drum magazine

- 24 tool places

- Tool change time from tool to tool: 2 seconds

Handwheel

- Portable; electronic

- Makes it easier to run programs

- Emergency stop push button

- Enabling button

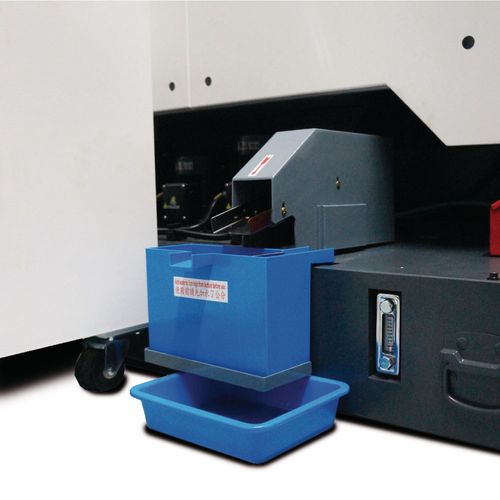

Oil separator / oil skimmer

- Oil skimmer reliably removes floating tramp oils and the finest swarf from cooling lubricants

Cleaning gun

- Easy cleaning of the work area

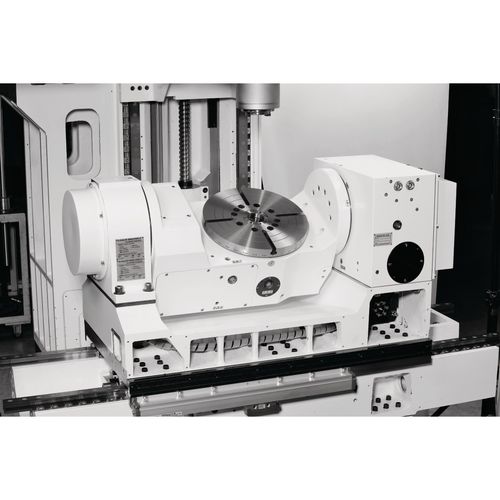

Swivel and rotary table

- Durable up to 100 kg

- Diameter 320 mm

Chip conveyor

- Belt version

- For efficient chip removal

Central lubrication

- Significantly prevents wear, repair costs and unnecessary downtime /li>

| Cooling lubricant system | |

|---|---|

| Tank capacity | 250 l |

| Dimensions and weights | |

|---|---|

| Max. length | 3110 mm |

| Length approx. | 2254 mm |

| Width/depth approx. | 2990 mm |

| Height approx. | 2960 mm |

| Weight approx. | 5000 kg |

| Electrical connections | |

|---|---|

| Total rated value | 31 kVA |

| Electrical Data | |

|---|---|

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Fast motion speed | |

|---|---|

| X axis | 48000 mm/min |

| Y axis | 48000 mm/min |

| Z axis | 48000 mm/min |

| Feed speed | |

|---|---|

| Acceleration X, Y, Z axis | 6 m/s² |

| Milling table horizontal | |

|---|---|

| Min. clearance vertical spindle - milling table | 100 mm |

| Max. clearance vertical spindle - milling table | 500 mm |

| T-groove size | 12 mm |

| Max. load bearing capacity | 100 kg |

| Pneumatic connection | |

|---|---|

| Operating pressure | 6 bar |

| Precision | |

|---|---|

| Repetition accuracy | ± 0,005 / 300 mm |

| Positioning accuracy | ± 0.005 mm |

| Rotary axis | |

|---|---|

| Swivel axis | + 120 / - 30 ° |

| Rotation axis | 360 ° |

| Rotary table diameter | 320 mm |

| Rotating table height | 1160 mm |

| Indexing A axis | 60 ″ |

| Indexing C axis | 20 ″ |

| Max. speed A axis | 25 min¯¹ |

| Max. speed C axis | 25 min¯¹ |

| Travel | |

|---|---|

| X axis automatic | 400 mm |

| Y axis automatic | 560 mm |

| Z axis automatic | 400 mm |

| Turret | |

|---|---|

| Design | Double arm gripper |

| Number of tool slots | 24 Tools |

| Max. tool diameter adjacent slots free | 130 mm |

| Max. tool diameter | 80 mm |

| Max. tool length | 245 mm |

| Max. tool weight | 8 kg |

| Tool change time chip to chip (C to C) | 9.33 s |

| Vertical spindle | |

|---|---|

| Spindle chuck | SK 40 DIN 69871 |

| Speed range | 15000 min¯¹ |

| Explanation speed range | Please note that the maximum spindle speed must be reduced by approx. 20 % in continuous operation. |

| Spindle centre to Z axis cover | 595 mm |

| Drive motor output continuous operation S1 | 15 kW |

| Drive motor output S6-30 % operation | 22.5 kW |

| Torque drive motor continuous operation S1 | 20 Nm |

| Torque drive motor S6-30 % operation | 62 Nm |

| VPE | 1 |

Packaging unit: 1

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.

Accessories

Optional parts

Optional parts can not be retrofitted and are available only when ordering new machines.