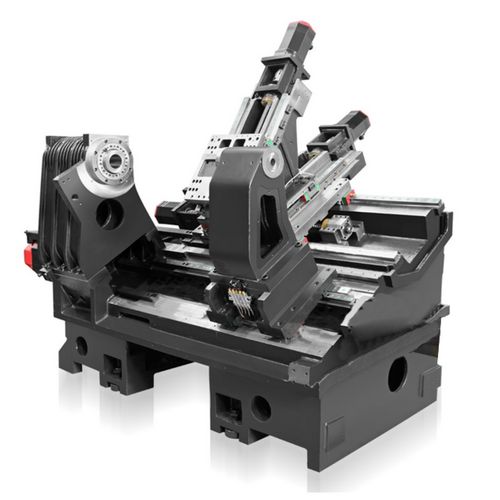

- Heavy-duty design

- Compact design

- Renishaw measuring arm for manual tool measurement

- Encoder on main spindle for increased accuracy

- The entire bed design features numerous reinforcing ribs optimized through finite element analysis, ensuring high rigidity, better heat dissipation (thermal symmetry), and more precise machining.

- Ball screw with improved accuracy, rigidity, and heat resistance.

- Siemens servo motors in all axes.

- All servo motors with integrated encoder for maximum accuracy.

- The motor is located on the side of the machine, preventing heat transfer and vibrations caused by the motor.

- 30° inclined bed design for particularly large machining diameters.

- Better, unhindered chip drainage into the Chip tray

- Hydraulic three-jaw lathe chuck Ø 250 mm with soft jaws

- BMT55 tool changer with 12 tool positions and driven tools

- Hardened and precision-ground ball screws for high rapid traverse speeds in all axes. Linear guide, except for the Y-axis, which has a box guide.

- Device for manual tool measurement

- Tailstock with hydraulic quill

- Air conditioning system

- Portable, electronic handwheel with enabling button and emergency stop push button makes program setup much easier.

- Belt-type chip conveyor ensures efficient chip removal.

- Work light for complete illumination of the work area.

- Coolant system with cleaning gun.

- BMT 55 tool changer

- RJ45 , power interface

- EMC (Electromagnetic Compatibility)

- Additional package SIEMENS material defect liability and free online/on-site service OSS Plus

- 1 year maintenance contract Basic included in D/A/CH

| Cooling lubricant system |

|---|

| Coolant pump output | 0.7 kW |

| Tank capacity | 320 l |

| Dimensions and weights |

|---|

| Length approx. | 5040 mm |

| Width/depth approx. | 1880 mm |

| Height approx. | 1990 mm |

| Weight approx. | 4700 kg |

| Electrical connections |

|---|

| Total rated value | 35 kVA |

| Electrical Data |

|---|

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Fast motion speed |

|---|

| X-axis | 24 m/min |

| Y-axis | 10 m/min |

| Y-axis | 30 m/min |

| Feed force |

|---|

| Feed force X-axis | 8.4 kN |

| Feed force Y-axis | 18 kN |

| Feed force Z-axis | 6.7 kN |

| Machine data |

|---|

| Chuck passage diameter | 74 mm |

| Angled bed | 30 ° |

| Motor torque |

|---|

| X axis | 12 Nm |

| Y axis | 12 Nm |

| Z axis | 12 Nm |

| Product information EU 2023/2854 |

|---|

| Type of the generated data | Usage data |

| Format of the generated data | Common, machine-readable formats such as JSON |

| Amount of data | Up to 5 MB |

| Continuous data generation in real time | Yes |

| Data storage location | On the device |

| Data access | Via physical interfaces |

| Further information | In the operating instructions or at info@stuermer-maschinen.de |

| Speed range |

|---|

| Speed range | 30 – 3500 min¯¹ |

| Spindle |

|---|

| Spindle chuck | A2-8 |

| Spindle bore with hydraulic chuck | 250 mm |

| Main spindle bore | 86 mm |

| Tailstock |

|---|

| Chuck | MK 5 |

| Quill stroke | 100 mm |

| Quill diameter | 100 mm |

| Travel |

|---|

| Travel X axis | 280 mm |

| Travel Z axis | 1280 mm |

| Y axis | ± 50 mm |

| Turret |

|---|

| Type | BMT55 |

| Number of tool slots | 12 |

| Drive motor output | 4.8 kW |

| Max. permissible speed at tool coupling | 4000 min¯¹ |

| Max. tool torque | 20 Nm |

| Vertical spindle |

|---|

| Drive motor output continuous operation S1 | 15 kW |

| Drive motor output S6-30 % operation | 19.5 kW |

| Drive motor torque | 268 Nm |

| Drive motor torque S6-30 % operation | 349 Nm |

| Work areas |

|---|

| Lathe chuck diameter | 500 mm |

| Turning length | 1250 mm |

| Swing diameter above machine bed | 660 mm |

| Swing diameter above planing slide | 480 mm |

Unit: pc(s).

Packaging unit: 1

- Axial tool holder driven tools

- Radial tool holder driven tools

- Boring bar holder

- OD tool holder

- End face tool holder

- Boring bar Ø 20 mm

- Boring bar Ø 25 mm

- Boring bar Ø 32 mm

Optimum Maschinen Germany GmbH

Dr.-Robert-Pfleger-Str. 26

Deutschland / Germany

96103 Hallstadt

info@optimum-maschinen.de