- Hardened and ground Z-axis guideway

- Guaranteed concentricity of the spindle nose ≤ 0.015 mm

- Spindle holder Camlock DIN ISO 702-2 No. 5

- Motor protection switch

- Main motor electrically braked

- Clockwise/anticlockwise rotation switchable on the bed slide

- Two-channel safety electronics

- Switch with life cycle calculation tested in accordance with EN ISO 13849

- Perfectly concentric main spindle guarantees high load capacity due to mounted precision tapered roller bearings

- With safety device to prevent simultaneous operation of tapping and feed mechanism

- Safety handwheels with disengagement function in the X and Z axes

- All gear wheels of the feed gear made of steel, hardened and ground, shafts on needle bearings All components are lubricated in an oil bath

- Simple feed operation

- One change gear position

- Switch cabinet with Optimum control system

- Coolant pump with coolant tank and level indicator. Container can be removed for easy cleaning

- LED machine lamp in the machine housing

- Machine base in sturdy steel construction

- Emergency stop switch on the right and left

- Lockable main switch

- Three-jaw lathe chuck included in the scope of delivery

- SWH included in scope of delivery

| Cooling lubricant system |

|---|

| Coolant pump output | 100 W |

| Dimensions and weights |

|---|

| Length approx. | 1935 mm |

| Width/depth approx. | 780 mm |

| Height approx. | 1740 mm |

| Weight approx. | 767 kg |

| Electrical Data |

|---|

| Drive motor output | 2,2 kW |

| Total rated value | 3,0 kW |

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Feed |

|---|

| Longitudinal feed range | 0,014 – 0,38 mm/rev |

| Flat feed range | 0,052 – 1,392 mm/rev |

| Pitches |

|---|

| Metric pitch | 0,4 – 7 mm/rev |

| Number of metric pitches | 32 |

| Imperial pitch | 56 – 4 Gg/1" |

| Number of imperial pitches | 31 |

| Speed range |

|---|

| Number of gears | 8 |

| Speed range | 70 – 2000 min¯¹ |

| Spindle |

|---|

| Spindle chuck | Camlock DIN ISO 702-2 No.5 |

| Spindle bore/rod passage diameter | 52 mm |

| Tool holder | SWH 3-E |

| Tailstock |

|---|

| Chuck | MT 4 |

| Quill stroke | 110 mm |

| Quill diameter | 50 mm |

| Tool clamping |

|---|

| Tool holder chuck size | 30 mm |

| Travel |

|---|

| Travel upper slide | 98 mm |

| Travel cross slide | 185 mm |

| Travel carriage saddle | 850 mm |

| Work areas |

|---|

| Center height | 200 mm |

| Distance between center | 1000 mm |

| Swing diameter above machine bed | 400 mm |

| Swing diameter above planing slide | 250 mm |

| Bed width | 203 mm |

| Explanation Swing diameter above planing slide | Please note that when installing third-party lathe chucks or faceplates to achieve the specified technically possible turning diameter, operator modifications are required. |

Unit: pc(s).

Packaging unit: 1

- Three-jaw lathe chuck Ø 200 mm, no. 5

- Quick change tool holder 3-E

- Fixed steady 7 - 102 mm

- Travelling steady 10 - 60 mm

- Reduction sleeve MT 6 - MT 4

- Fixed centre MT 4

- Machine initially filled with premium grade oil

- Operating tool

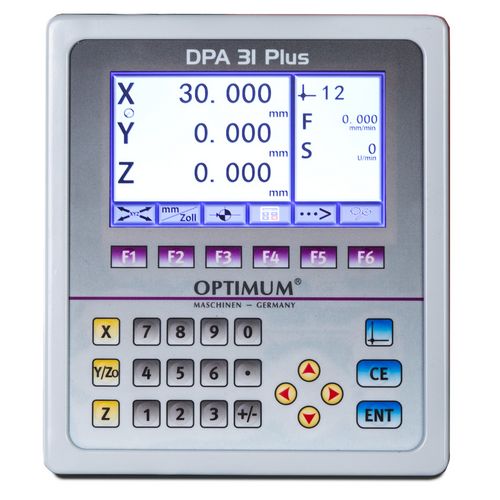

| Digital position indicator | DPA 31 Plus |

Optimum Maschinen Germany GmbH

Dr.-Robert-Pfleger-Str. 26

Deutschland / Germany

96103 Hallstadt

info@optimum-maschinen.de