- Hardened and ground Z-axis guideway

- Motor protection switch

- Control cabinet with 24 V DC power supply

- Partial enclosure with included, large dimensioned chip guard

- Chip guard with integrated position indicator, coolant hose and additional control panel

- Two-channel safety electronics

- Safety handwheels with disengaging function in the X- and Z-axis

- Face and top slide spindle is hardened and ground and adjustable via split spindle nut

- Lead and traction spindle cover

- Finely graduated feed and tapping range

- Energy chain for gentle guiding of cables and hoses

- Standard gears for metric thread pitches and modular threads are mounted in the machine. Change gears for inch and D.P threads optionally available

- Switches with life cycle calculation tested according to EN ISO 13849

- Decoupled handwheels tested according to EN 23125

- Reduction of main spindle deceleration time by energy regeneration

- Chip tray can be pulled out to the front

- Coolant device

- Quick-change steel holder SWH 5-B

- Steel holder 25 x 120 type D for square chisel 20 mm

- LED machine lamp for complete illumination of the working area

- Cutting constant VSC

You will receive the 3-year Stürmer warranty for this item when you register online.

| Cooling lubricant system |

|---|

| Coolant pump output | 0.125 kW |

| Tank capacity | 20 l |

| Dimensions and weights |

|---|

| Length approx. | 1960 mm |

| Width/depth approx. | 1060 mm |

| Height approx. | 1690 mm |

| Weight approx. | 1250 kg |

| Electrical Data |

|---|

| Drive motor output | 5.5 kW |

| Operating mode | S6 |

| Duty cycle | 60 % |

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Feed |

|---|

| Longitudinal feed range | 0.0263 – 1.8416 mm/rev |

| Number of longitudinal feeds | 48 |

| Flat feed range | 0.0133 – 0.9321 mm/rev |

| Number of flat feeds | 48 |

| Motor(s) |

|---|

| Drive motor gears | 2 |

| Pitches |

|---|

| Metric pitch | 0.2 – 14 mm/rev |

| Number of metric pitches | 36 |

| Imperial pitch | 80 – 1 Gg/1" |

| Number of imperial pitches | 42 |

| Diametrical pitch | 3 – 200 Gg/π |

| Number of diametrical pitches | 33 |

| Modular thread pitch | 0.1 – 7 mm/rev |

| Number of modular thread pitches | 44 |

| Product information EU 2023/2854 |

|---|

| Type of the generated data | Usage data |

| Format of the generated data | Common, machine-readable formats such as JSON |

| Amount of data | Up to 5 MB |

| Continuous data generation in real time | Yes |

| Data storage location | On the device |

| Data access | Via physical interfaces |

| Further information | In the operating instructions or at info@stuermer-maschinen.de |

| Speed range |

|---|

| Number of gears | 2 |

| Speed range | 50 – 3000 min¯¹ |

| Spindle |

|---|

| Spindle chuck | DIN ISO 702-1 No. 5 Form A2 |

| Spindle bore/rod passage diameter | 52 mm |

| Spindle cone | MT 6 |

| Standards and certifications |

|---|

| Standard | DIN EN 55011 |

| EMC level | C3 |

| Tailstock |

|---|

| Chuck | MK 3 |

| Quill stroke | 110 mm |

| Quill diameter | 50 mm |

| Travel |

|---|

| Travel upper slide | 112 mm |

| Travel cross slide | 212 mm |

| Travel carriage saddle | 800 mm |

| Work areas |

|---|

| Center height | 200 mm |

| Distance between center | 800 mm |

| Swing diameter above machine bed | 400 mm |

| Swing diameter above planing slide | 245 mm |

| Bed width | 260 mm |

Unit: pc(s).

Packaging unit: 1

- Fixed steady rest passage Ø 10 - Ø 130 mm

- Moving steady rest passage Ø 10 - Ø 100 mm

- Adapter MK6-MK3

- Non-moving centering tip MK3

- Non-moving, but temperature resistant

- Quick change steel holder SWH 5-B

- Steel holder 25x120 TypeD for square chisel 20 mm

- Initial machine filling with quality oil

- Operating tool

- Do not forget the lathe chuck

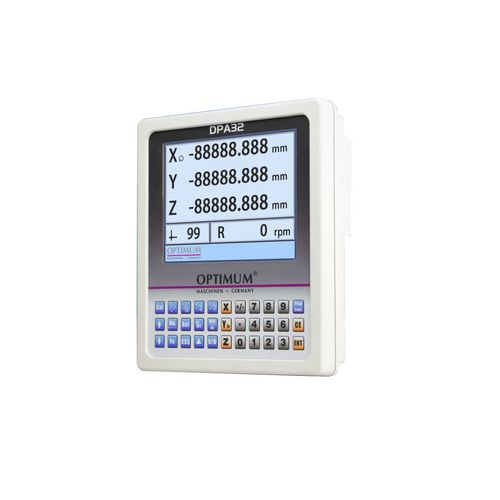

| Digital position indicator | DPA 32 |

Optimum Maschinen Germany GmbH

Dr.-Robert-Pfleger-Str. 26

Deutschland / Germany

96103 Hallstadt

info@optimum-maschinen.de