| Buffing unit | |

|---|---|

| Current draw | 2 x 0.14 kW |

| Speed | 2800 min¯¹ |

Edge bander

minimax me 40 tr s

For plastic edges from 0.4 - 3 mm, solid wood edges up to 5 mm and workpieces from 8 - 50 mm

58.131,50 EUR incl. 19% Tax / pc(s).

Promotional price *

37.149,00 EUR excl. Tax / pc(s).44.207,31 EUR incl. 19% Tax / pc(s).

Prices are recommended retail prices. Retailer prices may vary.

* Promotional price valid until 28.02.2026 in Germany.

Art.-No. 5507241

Productdetails

- Top equipment for high productivity with low space requirements!

- Intuitive operation with the eye-S control and 10" large touchscreen:

- HMI Maestro Active Edge

- Graphic display of all processing units and their operating status

- Graphic simulation of the machining operations

- Control of all processing units

- Regulation of the glue pool temperature

- Assistance functions for setting up the machine according to the machining program

- Fault diagnosis for quick correction of simple errors

- Statistics on machining parameters

- USB port

- Preparation for network connection

- Excellent accessibility to the working units thanks to the large hood that ensures protection and noise reduction

- Automatic aggregate positioning when changing plate thickness

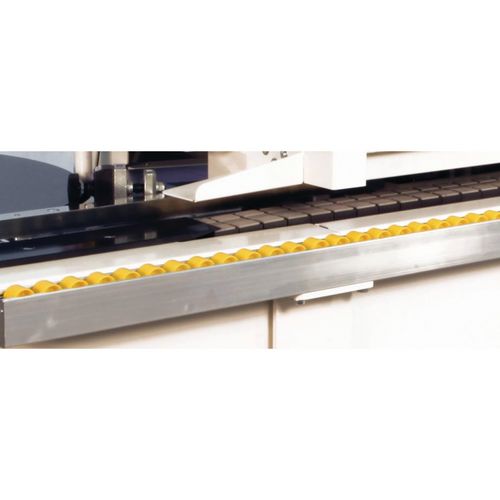

- Plate feed by conveyor with rubber sliders

- Quality Made in Italy

- Optimal machine management due to the new 10" touchscreen control panel with Maestro active edge on which all machine functions are displayed graphically

- Two slide cutter

- The glue is heated quickly and evenly by heating rods located both in the glue pot and in the glue application roller

- Automatic temperature reduction when the machine is in idle for longer

- Teflon-coated glue container for easy glue replacement

- Device for recycling of unused glue

- Automatic application of roll edges with cutting knife for edges up to 3 mm

- Turntable with Ø 730 mm

- Self-lubrication of the glue pot

- Kit for quick change of the glue container

- With sensing rollers in horizontal and vertical direction for optimal tool positioning

- Equipped with combination milling tool Ø 55.3 mm for flush milling of edges up to 5 mm and radius edges up to 2 mm

- Precise setting via 2 digital displays

- With chip exhaust

- Absolute cleanness for the perfect finish of workpiece surface

- With rotating copy device

- Drive via two independent swivel and height-adjustable motors

- For perfect cleaning and polishing of the panel edges

- With numerical position display

- For the perfect finishing of plastic edges

- With device for retracting the unit when it is not needed

- For automatic application of strip edges

- Solid wood strip edges are automatically loaded and synchronized with the panel guide

- Allows gluing and grooving of the workpiece in one pass

- Installation only possible as an alternative to buffing unit 5514560

- For capping the edge, as well as for radius milling on the top and bottom side

- The radius cutter is used to trim the edges when solid wood edges are glued

- High frequency motor with 12.000 rpm; saw blade Ø 125 mm Z12

- For pre-cleaning of the panel surface and edge for more effective cleaning

- For capping protruding edges

- For rounding the edges

- High frequency motor with 12,000 rpm; cutter Ø 58 mm Z4

Equipment details

10" touchscreen control panel

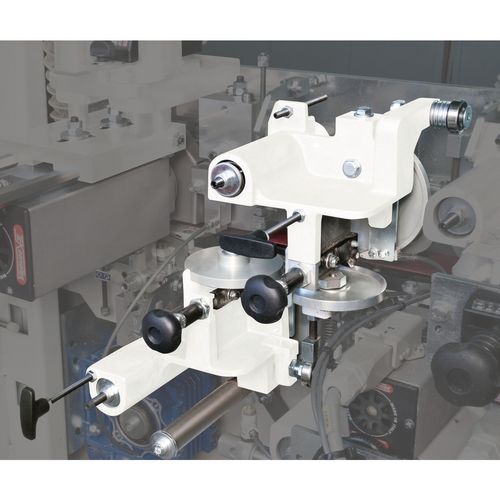

Premilling unit

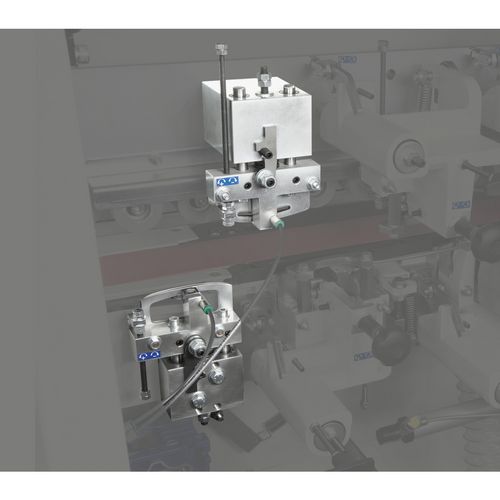

Gluing station

Flush radius trimming unit

Surface scraper

Buffing unit

Radius scraper

Edge magazine

Available as an option: Grooving unit

Milling unit (me 40 tr s)

Sprayer for finishing the edge

Cross-cut unit (me 40 tr s)

Rounding unit (me 40 tr s)

You will receive the 3-year Stürmer warranty for this item when you register online.

| Corner copy unit | |

|---|---|

| Current draw | 0.35 kW |

| Tool diameter | 58 mm |

| Speed | 12000 min¯¹ |

| Dimensions and weights | |

|---|---|

| Length approx. | 3774 mm |

| Width/depth approx. | 1546 mm |

| Height approx. | 1337 mm |

| Weight approx. | 842 kg |

| Electrical Data | |

|---|---|

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Feed | |

|---|---|

| Current draw | 0.55 kW |

| Speed | 9 m/min |

| Flush radius milling unit | |

|---|---|

| Current draw | 2 x 0.35 kW |

| Miller diameter HM | 55.3 mm |

| Miller speed | 12000 min¯¹ |

| Extraction port diameter | 60 mm |

| Number of extraction ports | 2 |

| Gluing unit | |

|---|---|

| Current draw | 0.25 kW |

| Extraction port diameter | 60 mm |

| Filling quantity | 0.8 kg |

| Pre-milling unit | |

|---|---|

| Extraction port Ø | 2 x 80 mm |

| Current draw | 3 kW |

| Milling speed | 7200 min¯¹ |

| Diamond milling diameter | 80 mm |

| Milling height | 56 mm |

| Material removal | 0 – 2 mm |

| Product information EU 2023/2854 | |

|---|---|

| Type of the generated data | Usage data |

| Format of the generated data | Common, machine-readable formats such as JSON |

| Amount of data | Up to 5 MB |

| Continuous data generation in real time | Yes |

| Data storage location | On the device and a remote server |

| Data access | On the device and physical and wireless interfaces |

| Further information | In the operating instructions or at info@stuermer-maschinen.de |

| Scraper blade units | |

|---|---|

| Radius scraper | 2 mm |

| Workpiece | |

|---|---|

| Thickness | 8 – 50 mm |

| Minimum length | 120 mm |

| Min. width | 110 mm |

| VPE | 1 |

| Sicherheits- und Warnhinweise | |

| Safety and warning notices |

Packaging unit: 1

| Roller edge rotary platen | 730 mm |

| Edge magazine | ✔ |

| Anti-adhesive spraying unit | ✔ |

| Pre-milling unit | with two slide cutters |

| Edge preheating device | with ceramic infrared lamp |

| Glue container quick-change kit | ✔ |

| Bonding unit | ✔ |

| Jack knife | ✔ |

| Corner copy unit | ✔ |

| Flush radius milling unit | ✔, can be switched off manually |

| Radius scraper unit | Can be switched off manually, with numerical position display |

| Area scraper unit | Can be switched off manually, with rotating copying device |

| Buffing unit | ✔ |

| Cleaning spray unit | ✔ |

Dr.-Robert-Pfleger-Str. 26

96103 Hallstadt

Deutschland / Germany

info@stuermer-maschinen.de

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.

Accessories

Optional parts

Optional parts can not be retrofitted and are available only when ordering new machines.