| Data sheets | |

|---|---|

| Sicherheits- und Warnhinweise | |

| Safety and warning notices |

Laser welder

Craft-Laser 1500 S

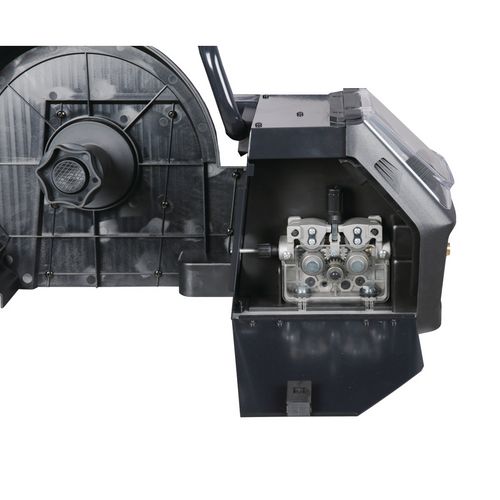

Device with wire feed case, large LCD display and trolley

Price upon request

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 1390015

Productdetails

Basic Features

Method

Description

Operation

- Extremely simple operation thanks to synergy curves

- Three steps to the finished welding result. Automatic adjustment of power, wire feed, oscillation width, oscillation frequency, laser frequency, PWM, hot start, etc.

- High-resolution display enables optimum readability of all necessary parameters. Integrated help ensures better understanding of the setting options

- Fully integrated operation in the wire feed case - optional operation via machine or wire feed

Technical features

- 20µm single-mode laser sources. Double the power density of the standard 50µm multi-mode laser sources of many competitors ensure significantly higher penetration depths and beam qualities.

- High-performance laser cells paired with gas-cooled torches ensure maximum power and focus stability.

- 2-in-1 machine: welding and cleaning: Laser cleaning is perfect for paint stripping, rust removal and scale removal

- Optional: Ethernet-IP interface for robot applications

- Optional: double wire feed

Safety and security

- 2-channel emergency stop system

- 2-channel safety interface for access monitoring (door contact switch)

- Key switch to prevent unauthorized use

- 2-channel fiber breakage detection and monitored QBH connection

- Safety instructions and manual activation of laser release at each start

- Double push button prevents unintentional activation of the laser

- Water-cooled

- Suitable for heavy-duty applications

Advantages of laser welding compared to conventional welding processes

- Hardly any distortion, incredibly fast, incredibly good quality (even with very thin materials <1 mm)

- Consumes approx. 70% less energy

- Quick and easy to learn

- High process reliability

- Extreme time savings with greatly reduced rework at the same time

- One of the lightest torches on the market at approx. 680 g

- 2-channel safety loop for maximum safety

Advantages of the Craft laser

- Laser cleaning with up to 100 mm scan width with autofocus

- 2-in-1 machine: welding and cleaning

- Complete synergy - no more parameter lists

- Service-friendly - no more inconvenient sending in

- Problem-free processing of steel, stainless steel, aluminum, brass

- Extremely simple machine operation thanks to complete synergy characteristics

- Machine can also handle laser cleaning up to 100 mm scan width

- Great savings potential thanks to three to four times faster processing and a reduction in the error rate

- Low heat input into the workpiece

- With wobble function

- Simple operation with laser welding gun and automatic wire feed: High-quality weld seams, even without many years of welding experience

- On/off switch for the wire feed directly on the laser gun

| Cooling | |

|---|---|

| Cooling type | air-cooled |

| Dimensions and weights | |

|---|---|

| Weight power source | 53 kg |

| Weight wire feed case | 11.5 kg |

| Length approx. | 750 mm |

| Width/depth approx. | 600 mm |

| Height approx. | 1000 mm |

| Weight approx. | 130 kg |

| Electrical connections | |

|---|---|

| Power consumption in idle mode | < 70 W |

| Input Power | 4.8 kW |

| Output Power | 1.5 kW |

| Electrical Data | |

|---|---|

| Supply voltage | 230 V |

| Mains frequency | 50 Hz |

| Input | |

|---|---|

| Efficiency | 30 % |

| Laser | |

|---|---|

| Wobble from to | 0 5 mm |

| Spectrum width from to | 3 – 4 nm |

| Red guide laser power | 200 µW |

| Max. Average power Visible radiation | 0.2 mW |

| Max. Average power Invisible radiation | 1500 W |

| Wavelength range Visible radiation | 640±10 nm |

| Wavelength range Invisible radiation | 1080±10 nm |

| Laser class Visible radiation | 2 |

| Laser class Invisible radiation | 4 |

| Product information EU 2023/2854 | |

|---|---|

| Type of the generated data | Usage data |

| Format of the generated data | Common, machine-readable formats such as JSON |

| Amount of data | Up to 5 MB |

| Continuous data generation in real time | Yes |

| Setting range | |

|---|---|

| Setting range for 230 V | 5 – 1500 W |

| Weldable material thickness | |

|---|---|

| weldable material thickness steel | 0.8 – 6 mm |

| weldable material thickness stainless steel | 0.8 – 6 mm |

| weldable material thickness aluminum | 0.8 – 4 mm |

| Wire feed | |

|---|---|

| weldable wires steel | 0.6 – 1.6 mm |

| weldable wires stainless steel | 0.6 – 1.6 mm |

| weldable wires aluminium | 1.0 – 1.6 mm |

| Wire feet unit | 4 Rollers |

| Wire feed speed | 0.25 6 m/min |

| VPE | 1 |

Packaging unit: 1

- Welding gun

- Gas hose 4 m

- 5 protective glasses for laser welding gun

- 2 conveyor rollers 0.8 / 1.0 V-groove

- 2 conveyor rollers 1.0 / 1.2 V-groove

- 2 conveyor rollers 1.2 / 1.6 V-groove

- 2 conveyor rollers 0.8 / 1.0 U-groove

- 2 conveyor rollers 1.0 / 1.2 U-groove

- 2 conveyor rollers 1.2 / 1.6 U-groove

- 3 nozzles AS-12 for laser welding gun

- 3 nozzles ES-12 for laser welding gun

- 3 BS-16 nozzles for laser welding gun

- 3 cutting nozzles

- Laser cleaning accessories

- Filter pressure regulator 1/4" 16 bar

- Plug nipple with external thread 1/4" AG

- Double nipple G 1/4" x G 1/4"

- Faceshield FS 1 (golden visor)

Dr.-Robert-Pfleger-Str. 26

96103 Hallstadt

Deutschland / Germany

info@stuermer-maschinen.de

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.