| Cooling lubricant system | |

|---|---|

| Coolant pump(s) drive power | 0,55 kW |

| Tank capacity | 500 l |

| Tank capacity CTS | 230 l |

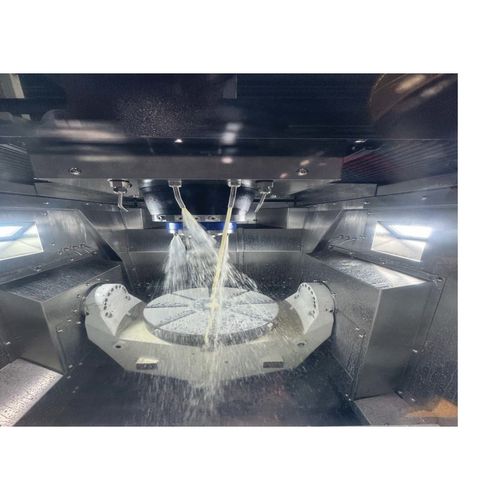

CNC milling machine

OPTImill FU 450

5-axis simultaneous machining center for maximum productivity

Price upon request

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 3522100

Productdetails

- Heavy-duty design

- High productivity

- Telescopic guideway cover

- Precision-ground, preloaded high-performance ball screws for high rapid traverse speeds

- Spindle mounted in P5 precision bearings and permanently lubricated

- High-torque servo drives in all five axes

- Precision linear guide

- Heidenhain glass scales for higher accuracy

- High rapid traverse speed of up to 40 m/min.

- C-axis with torque motor for maximum speed and lifetime accuracy

- A-axis with worm gear for high torque during tilting operations

- Z-axis feed motor reinforced

- The portable, electronic handwheel with enabling switch and emergency stop switch makes it much easier to run in programs

- Tool changer double-arm gripper with 40 tool positions included as standard

- Coolant system with 380 liter coolant tank with chip flushing system and cleaning gun

- Automatic central lubrication

- RJ45 plug connection, USB and 230 V power connection

- Additional USB interface on the control panel

- Water circuit cooling unit for the main spindle and main spindle motor

- Chip conveyor in belt design ensures efficient chip removal

- Chip trolley

- Collision avoidance software for collision avoidance

- Internal spindle cooling 40 bar with internal tank (an extraction unit is required)

- Air conditioning

- Encoder for A and C axis

- TSC Thermal spindle compensation

- DCM Dynamic collision monitoring

- EMC (electromagnetic compatibility)

- Two-year SIEMENS repair service contract included. Extension of the SIEMENS additional package repair service contract (RSV) possible

| Dimensions and weights | |

|---|---|

| Length approx. | 3400 mm |

| Width/depth approx. | 3500 mm |

| Height approx. | 2940 mm |

| Weight approx. | 8000 kg |

| Electrical Data | |

|---|---|

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Fast motion speed | |

|---|---|

| X axis | 48000 mm/min |

| Y axis | 48000 mm/min |

| Z axis | 40000 mm/min |

| Milling table horizontal | |

|---|---|

| Table length | 750 mm |

| T-groove size | 14 mm |

| Max. load bearing capacity | 300 kg |

| Pneumatic connection | |

|---|---|

| Operating pressure | 6 bar |

| Precision | |

|---|---|

| Repetition accuracy | ± 0.003 mm |

| Positioning accuracy | ± 0.004 mm |

| Product information EU 2023/2854 | |

|---|---|

| Type of the generated data | Usage data |

| Format of the generated data | Common, machine-readable formats such as JSON |

| Amount of data | Up to 5 MB |

| Continuous data generation in real time | Yes |

| Data storage location | On the device |

| Data access | Via physical interfaces |

| Further information | In the operating instructions or at info@stuermer-maschinen.de |

| Pump | |

|---|---|

| Pump motor chip flushing | 3 kW |

| Pump motor cleaning gun | 3 kW |

| Rotary axis | |

|---|---|

| Rotary axis max. permissible torque (S1) | 340 Nm |

| Rotary axis max. permissible torque (S6) | 340 Nm |

| Swivel axis | ± 120 ° |

| Rotation axis | 360 ° |

| Rotary table diameter | 450 mm |

| Max. speed A axis | 50 min¯¹ |

| Max. speed C axis | 80 min¯¹ |

| Swivel axis max. permissible torque (S1) | 1200 Nm |

| Swivel axis max. permissible torque (S6) | 1200 Nm |

| Tilting and rotating table | |

|---|---|

| Hydraulic clamping torque swivel axis C (at 50 bar hydraulic pressure) | 650 Nm |

| Hydraulic clamping torque swivel axis A (at 50 bar hydraulic pressure) | 2500 Nm |

| Travel | |

|---|---|

| X axis automatic | 450 mm |

| Y axis automatic | 500 mm |

| Y axis milling head | 400 mm |

| Turret | |

|---|---|

| Design | Double arm gripper |

| Number of tool slots | 40 |

| Max. tool diameter adjacent slots free | 120 mm |

| Max. tool diameter | 80 mm |

| Max. tool length | 300 mm |

| Max. tool weight | 8 kg |

| Tool change time chip to chip (C to C) | 3.5 s |

| Vertical spindle | |

|---|---|

| Spindle chuck | HSK 63 DIN 69893 |

| Speed range | 10 18000 min¯¹ |

| Drive motor output continuous operation S1 | 15 kW |

| Drive motor output S6-30 % operation | 18,5 kW |

| Torque drive motor continuous operation S1 | 33,2 kW |

| Torque drive motor S6-30 % operation | 45,2 kW |

| VPE | 1 |

| Sicherheits- und Warnhinweise | |

| Safety and warning notices |

Packaging unit: 1

Dr.-Robert-Pfleger-Str. 26

Deutschland / Germany

96103 Hallstadt

info@optimum-maschinen.de

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.

Accessories

Optional parts

Optional parts can not be retrofitted and are available only when ordering new machines.