| Control | |

|---|---|

| Type of Control | Sinumerik 828D PPU 271 |

| Sinumerik 828D system software (factory option) | SW 24 |

| CNC memory | 3 MB |

| Look Ahead | 50 |

| Set change time | 3 ms |

| Number of tools | 128 |

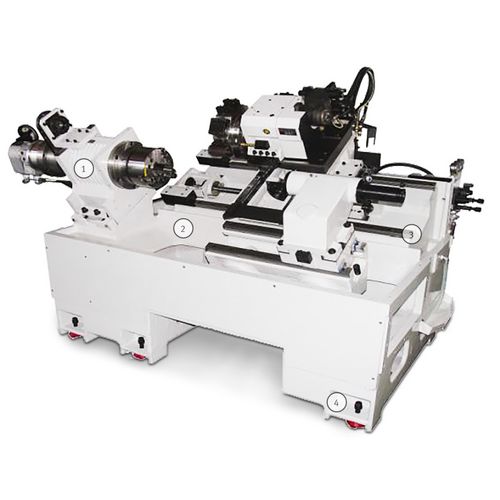

CNC slant bed lathe

OPTIturn S 600

PREMIUM machine characterized by high speed, performance, precision and durability. With Siemens control 828D Basic

Price upon request

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 3515060

Productdetails

- Robust construction

- Compact design

- SIEMENS servomotors in all axes

- All servomotors with integrated encoder for maximum accuracy

- Inclined bed version 30° for particularly large machining diameters

- Better, unimpeded chip drainage into the chip tray

- Hydraulic three-jaw lathe chuck Ø 200 mm

- Hard and soft block jaws

- Standard tool changer VDI 30 with 8 tool places

- Hardened and precision ground recirculating ball spindles for high rapid traverse speeds in all axes

- Dimensionally stable linear guides ensure a long service life thanks to maximum static and dynamic rigidity

- Device for manual tool measurement

- Tailstock with hydraulic quill

- Heat exchanger

- Portable, electronic handwheel with enabling button and emergency stop push button makes it easier to retract programs considerably

- Chip conveyor in belt design for efficient chip removal

- Chip trolley

- Halogen work light for complete illumination of the work area

- Coolant system

- EMC (electromagnetic compatibility)

SINUMERIK 828D Basic

High-tech for the compact class

Increased productivity and precision in production

The use of two independently working tools makes 4-axis turning (balance cutting) possible. The new functions include multi-channel functionality with ShopTurn, which among other things allows programs to be synchronized with programSYNC. The new software offers the option of running two channels in lathes and grinding machines at the same time. The SINUMERIK CNC control 828D Basic sets standards in all aspects of machining performance. Whether accuracy and speed, whether reducing cycle times or energy efficiency and safety - SINUMERIK sets the pace.

SHOPTURN

- Shortest programming time for the production of individual parts and small series

DXF READER

- Faster from drawing to component. Easy transfer of the CAD data into the programming by DXF-READER (optional article no. 3584014).

COMPLETE PACKAGE

- Safety Integrated

- Residual material detection and processing

- ShopTurn work step programming

- Manage network drive

- 3-D simulation

- Simultaneous drawing

Control

- 10.4" color display

- 4:3 format

- User-friendly SINUMERIK Operate software

- Front interfaces: USB 2.0, RJ45 Ethernet, Compact Flash (CF) card

- Thanks to the 8 horizontal and 8 vertical Softkeys can be accessed with just a few keystrokes in all operating masks

- Durable and robust

Extended warranty

With the extended warranty you protect your new machine against warranty damage for a further 12 or 36 months (only to be bought with purchase of machine).

- 12 months; Article No. 3589020

- 36 months; Article No. 3589022

SIEMENS SAFETY INTEGRATED

Functional safety also protects against high costs!

Machine and system safety is not only important because strict regulations have to be observed. If everything runs safely, you benefit from time savings in engineering, higher system availability and more investment security.

Equipment

Components and cast parts

- Guarantees high rigidity

Machine bed

- Heavily ribbed

- 30 degree incline

- High rigidity and durability

Linear guide

- Maximum static and dynamic rigidity

- High positioning accuracy

- Smooth, play-free movement

Machine feet

- Six pieces

- Optimal alignment of the machine

Separator

- Separates the lubricant from the coolant

Tool change system

- Eight tool places

- VDI 30 tool changer

Tailstock quill

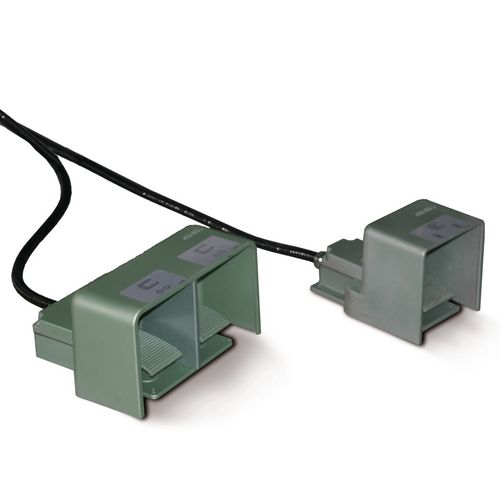

- The tailstock quill is moved hydraulically with the foot switches

- Hydraulic quill stroke 60 mm

- Faster processing

Hydraulic unit

- Safety check valve

- Motor power 1.5 kW

- Tank capacity 60 liters

Tool probe

- By Renishaw

- Allows tools to be measured inside the machine

Three-jaw chuck

- Hydraulic three-jaw lathe chuck Ø 200 mm

- Passage Ø 65 mm

- Easy clamping of workpieces

Automatic lubrication system

- Can be folded out

- With float switch. If the oil level is too low, an acoustic signal sounds

Coolant tank

- Pull-out chip tray

- Pull-out coolant reservoir

- Level indicator

- Tank capacity 140 liters

Foot pedal

- For loosening and clamping the lathe chuck

- Hydraulic extension or retraction of the optional tailstock quill

| Cooling lubricant system | |

|---|---|

| Coolant pump output | 750 W |

| Tank capacity | 140 l |

| Cleaning pump output | 750 W |

| Dimensions and weights | |

|---|---|

| Length approx. | 2322 mm |

| Width/depth approx. | 1948 mm |

| Height approx. | 1930 mm |

| Weight approx. | 3200 kg |

| Electrical connections | |

|---|---|

| Total rated value | 31 kVA |

| Electrical Data | |

|---|---|

| Drive motor output | 12 kW |

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Feed force | |

|---|---|

| Feed force X-axis | 6.9 kN |

| Feed force Z-axis | 6.9 kN |

| Feed speed | |

|---|---|

| X axis | 30000 mm/min |

| Z axis | 30000 mm/min |

| Hydraulic system | |

|---|---|

| Motor output | 1,5 kW |

| Tank capacity | 60 l |

| Machine data | |

|---|---|

| Chuck passage diameter | 65 mm |

| Angled bed | 30 ° |

| Motor torque | |

|---|---|

| X axis | 11 Nm |

| Z axis | 11 Nm |

| Motor(s) | |

|---|---|

| Drive motor torque | 115 Nm |

| Precision | |

|---|---|

| Repetition accuracy | ± 0.005 mm |

| Positioning accuracy | ± 0.005 mm |

| Speed range | |

|---|---|

| Speed range | 40 – 4000 min¯¹ |

| Spindle | |

|---|---|

| Spindle chuck | DIN ISO 702-1 No. 6 |

| Spindle bore/rod passage diameter | 75 mm |

| Tailstock | |

|---|---|

| Chuck | MT 4 |

| Quill stroke | 60 mm |

| Quill diameter | 65 mm |

| Travel | 425 mm |

| Quill stroke actuation | hydraulic |

| Turret | |

|---|---|

| Type | VDI 30 |

| Number of tool slots | 8 |

| Vertical spindle | |

|---|---|

| Drive motor output continuous operation S1 | 12 kW |

| Drive motor output S6-30 % operation | 30 kW |

| Drive motor torque | 115 Nm |

| Drive motor torque S6-30 % operation | 250 Nm |

| Work areas | |

|---|---|

| Lathe chuck diameter | 200 mm |

| Lathe chuck actuation of clamping movement | hydraulic |

| Turning length | 460 mm |

| Max. height | 250 mm |

| Swing diameter above machine bed | 500 mm |

| Swing diameter above planing slide | 220 mm |

| VPE | 1 |

Packaging unit: 1

- Tool probe Renishaw

- Tool holder for MK3

- EMC

- Coolant system

- Portable electronic handwheel

- heat exchangers

- Hydraulic tool turret LS200 standard

- chip conveyor

- Hydraulic 3-jaw chuck Ø 200 mm

- chip cart

- Hard and soft block cheeks

- operating tool

- Tool holder set 3 Holder for reducing sleeves, 1 holder for external turning steel, 5 reduction sleeves Ø 12 mm, Ø 16 mm, Ø 20 mm, Ø 25 mm, MK 3

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.