Productdetails

- Machine bed made of heavily ribbed cast iron

- One-piece machine base made of steel

- High rigidity of the headstock housing due to heavily ribbed 25GG casting

- Precisely machined slide

- Shafts on needle bearings, all components are lubricated in an oil bath

- Bed guides hardened and precision ground

- All electronic controls can be reached centrally

- All gear wheels of the feed gear made of steel, hardened and ground

- Handwheels decoupled and tested in accordance with EN 23125

- Two-channel safety electronics

- Switch with life cycle calculation, tested in accordance with EN ISO 13849

- Complete lead and pull spindle cover

- Complete illumination of the work area

- Service-friendly removable rear panel

- Hardened and ground face spindle ensures enormous accuracy and durability

- High chip removal during roughing is no problem thanks to the high cutting capacity

- Energy chain for gentle cable and hose guidance

- Lockable chip guard moves with the bed slide with integrated position indicator and coolant hose, can be moved manually

- No change wheels necessary

- With safety device to prevent simultaneous operation of tapping and feed mechanism

- Electronic feed switch-off of the Z-axis

- Coolant device with separate coolant tank with level indicator and oil separator; easy and complete emptying and cleaning according to DIN

- Electric position switch-off with quadruple position stop

- Three-jaw lathe chuck included as standard

- Quick-change steel holder SWH 7-C

- Steel holder 32 x 130 type D for square chisel 25 mm

- Large spindle bore

| Cooling lubricant system |

|---|

| Coolant pump output | 60 W |

| Dimensions and weights |

|---|

| Length approx. | 2925 mm |

| Width/depth approx. | 1195 mm |

| Height approx. | 1930 mm |

| Weight approx. | 2470 kg |

| Electrical connections |

|---|

| Total rated value | 5.5 kW |

| Electrical Data |

|---|

| Drive motor output | 5.5 kW |

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Feed |

|---|

| Longitudinal feed range | 0,05 – 1,5 mm/rev |

| Number of longitudinal feeds | 55 |

| Flat feed range | 0,025 – 0,75 mm/rev |

| Number of flat feeds | 55 |

| Pitches |

|---|

| Metric pitch | 0,5 - 15 mm/rev |

| Number of metric pitches | 55 |

| Imperial pitch | 60 – 2 Gg/1" |

| Number of imperial pitches | 55 |

| Diametrical pitch | 120 – 4 Gg/π |

| Number of diametrical pitches | 55 |

| Modular thread pitch | 0,25 – 7,5 mm x π |

| Number of modular thread pitches | 55 |

| Speed range |

|---|

| Number of gears | 2 x 3 Steps |

| Speed range | 12 – 1800 min¯¹ |

| Spindle |

|---|

| Spindle chuck | Camlock DIN ISO 702-2 No. 8 |

| Spindle bore/rod passage diameter | 80 mm |

| Tool holder | SWH 7C |

| Spindle cone | MT 7 |

| Tailstock |

|---|

| Chuck | MK 5 |

| Quill stroke | 180 mm |

| Quill diameter | 72 mm |

| Travel |

|---|

| Travel upper slide | 170 mm |

| Travel cross slide | 340 mm |

| Travel carriage saddle | 1400 mm |

| Work areas |

|---|

| Max. height | 260 mm |

| Max. width | 1600 mm |

| Swing diameter above machine bed | 520 mm |

| Swing diameter above planing slide | 324 mm |

| Bed width | 350 mm |

Unit: pc(s).

Packaging unit: 1

- Three-jaw lathe chucks Ø 315 mm No. 8

- Fixed center point MT 5, long

- Fixed center point MT 5, short

- Operating tool

- Initial machine filling with quality oil

- Quick-change steel holder SWH 7C

- Steel holder for square chisels 32 x 130 type D for square chisels 25 mm

- Reducing sleeve MT 7 / MT 5

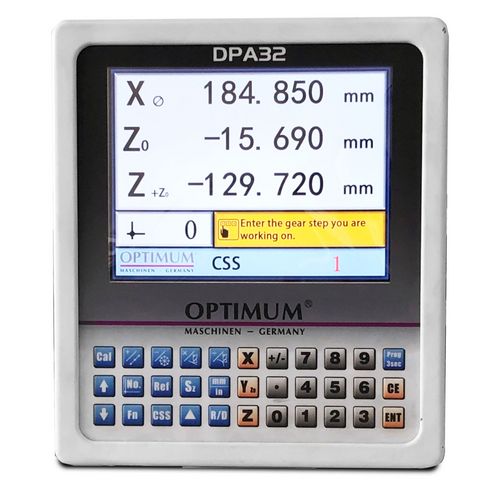

| Digital position indicator | DPA 32 |