| Dimensions and weights | |

|---|---|

| Length approx. | 850 mm |

| Width/depth approx. | 1030 mm |

| Height approx. | 1340 mm |

| Weight approx. | 318 kg |

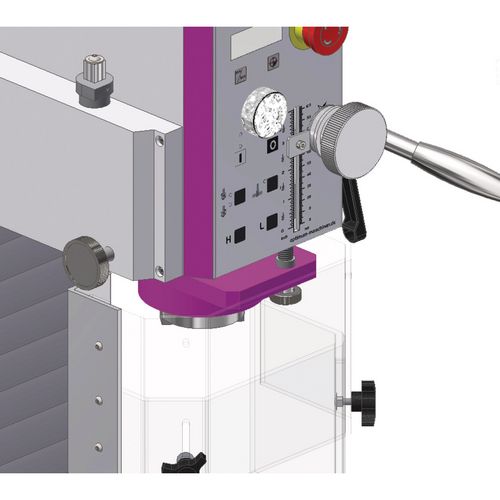

Drilling-milling machine

OPTImill MH 35V

Universal precision drilling and milling machines with manual gearbox

6.396,25 EUR incl. 19% Tax / pc(s).

Promotional price *

5.099,00 EUR excl. Tax / pc(s).6.067,81 EUR incl. 19% Tax / pc(s).

Prices are recommended retail prices. Retailer prices may vary.

* Promotional price valid until 28.02.2026 in Germany.

Art.-No. 3338171

Productdetails

- High concentricity due to tapered roller bearings, ≤ 0.015 mm measured in the sleeve

- Solid and generously dimensioned cross table, precisely surface-machined with T-slots

- Control panel with user-friendly, dirt and water-resistant membrane keypad

- Easy-to-read digital display

- Drilling depth stop

- Right/left rotation

- Thread cutting mode

- Rotary pushbutton in the control panel for setting the drilling depth in either mm or inches and zero point

- Height-adjustable protective screen with microswitch, against flying chips and parts, for maximum user protection

- Gear head can be tilted ± 30

- Adjustable and readjustable feed spindle play

- Heavy, stable and solid column made of high-quality gray cast iron, with ground and scraped dovetail guide for high stability and precision as well as adjustable gibs

- Z-axis with stainless steel lamella protective cover

- Optional, solid, heavy steel base MSM 3 (item no.: 3353014) ensures stability

- Two-stage industrial motor and additional 6 gear stages

Updated version

- Machine base reinforced and cast in a wedge shape at the front to create even more rigidity in the rear area with more material. The entire table can be milled over

- Z-column connection very stable

MH 35V

- Electric Z-axis adjustment

- Larger table and therefore more travel in X-axis

| Drilling/milling head | |

|---|---|

| Drill-mill head tilt range | ± 30 ° |

| Drilling/milling output | |

|---|---|

| Max. size milling head | 80 mm |

| Max. size shaft milling cutter | 28 mm |

| Drilling performance steel (S235JR) | 32 mm |

| Continuous drilling performance steel (S235JR) | 28 mm |

| Electrical Data | |

|---|---|

| Drive motor output | 1,1 / 1,5 kW |

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Milling table horizontal | |

|---|---|

| Table length | 750 mm |

| Table width | 210 mm |

| Max. clearance vertical spindle - milling table | 440 mm |

| T-groove size | 12 mm |

| T-groove number | 3 |

| T-groove spacing | 63 mm |

| Max. load bearing capacity | 170 kg |

| Product information EU 2023/2854 | |

|---|---|

| Type of the generated data | Usage data |

| Format of the generated data | Common, machine-readable formats such as JSON |

| Amount of data | Up to 5 MB |

| Continuous data generation in real time | Yes |

| Data storage location | On the device |

| Data access | Via physical interfaces |

| Further information | In the operating instructions or at info@stuermer-maschinen.de |

| Standards and certifications | |

|---|---|

| Standard | DIN EN 55011 |

| EMC level | C2 |

| Travel | |

|---|---|

| X axis manual | 450 mm |

| Y axis manual | 200 mm |

| Z axis manual | 460 mm |

| Vertical spindle | |

|---|---|

| Reach | 215 mm |

| Spindle chuck | BT 30 |

| Speed range | 220 – 3100 min¯¹ |

| Number of gears | 2 x 6 Steps |

| Quill diameter | 68 mm |

| Quill stroke | 90 mm |

| VPE | 1 |

| Sicherheits- und Warnhinweise | |

| Safety and warning notices |

Packaging unit: 1

- Operating tool

Dr.-Robert-Pfleger-Str. 26

Deutschland / Germany

96103 Hallstadt

info@optimum-maschinen.de

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.