In cooperation with the University of Trier and a German engineering company, OPTIMUM Maschinen Germany GmbH has developed a new 3D printing head that enables 5-axis 3D printing on the OPTIMUM FU5 CNC milling machine or another 5-axis milling machine with Siemens 840DSL control using Siemens NX software.

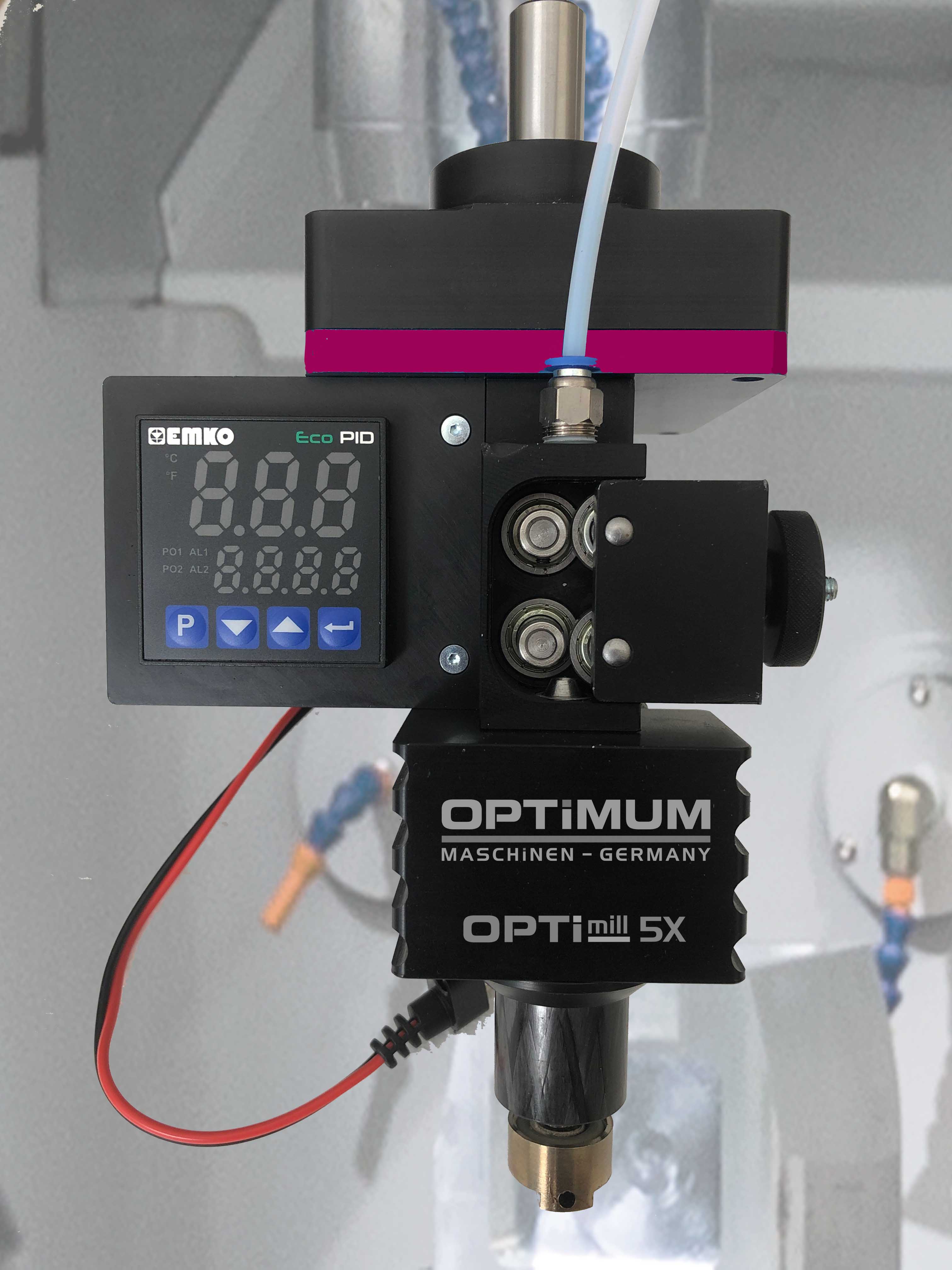

The new print head 5X is a further development of the well-known 3-axis print head Optimill 3X, which has already been successfully in use as a machine component to OPTIMUM's CNC milling machines since 2018. Compared to the 3-axis printing process, however, Optimill 5X brings a clear advantage: printing on five axes not only saves time, but also achieves greater stability of the printed components. The material can be printed in the course of the component's load direction. A 3-axis 3D printing requires support structures from an angle of around 60 °, which are printed together with the component. This requires an increased amount of time and material, as the support structures have to be removed again after printing. By adding the fourth and fifth axes, the new Optimill 5X print head can now dispense with such support structures and print such component in one piece without any supports. This improves the surfaces and staircase effect can be avoided.

As part of this new development, OPTIMUM has revised and optimized various other components of the 3D printing head so that even more precise results can be achieved in the future. For example, the cantilever length of the hot end has been improved to reduce interfering edges, and the heating has been converted to toroidal core heating. The improvement of the heating results in more even and faster melting of the filament. As a result, large flow rates can also be realized. This is necessary to speed up the printing process and / or to work with large nozzle diameters.

In order to exploit all the functionalities of the Optimill 5X print head, we recommend using the Siemens NX software, as OPTIMUM can offer a suitable post processor and machine integration for this purpose. However, other CAD / CAM systems are also able to program the complex 5-axis motion control. In this case it is advisable to consult with the provider to ensure that the created post-processor is compatible with the OPTIMUM hardware. Of course, you always have the option of using the Optimill 5X printhead to perform standard 3-axis printing. For this, you use the Cura programming software.

5-axis printing using Siemens NX

In order to be able to carry out not only the planning but also a complete simulation of the machine tool in Siemens NX, several requirements must be met: First, a 3D model of the machine tool must be available that has been previously kinematized and has a stored postprocessor. Secondly, the print head required for production must also be stored as a model in order to be able to represent a realistic simulation. In addition, the component to be printed must be created as a model before production. This can either be designed directly in NX or you can use alternative systems and file formats and then import the models into NX.