The 5-axis machining center OPTImill FU5, which Optimum Maschinen Germany GmbH provided to the Umwelt-Campus Birkenfeld a few months ago for 3D printing trials, impressed across the board during a test trial in January 2020. Even under the camera microscope used, hardly any defects could be detected on the test pieces milled by the Optimum machine.

The CNC milling machine was tested using a test workpiece developed by the NC Gesellschaft e.V. in 2005 to investigate the dynamic synchronization of machine axes and milling operations. During a workshop with Hans Vogler, one of the developers of the test piece and a luminary in the field of NC control, the OPTImill FU5 was thoroughly checked at the Environmental Campus Birkenfeld in the presence of representatives from Optimum and Siemens AG.

In a first step, Siemens application engineer Wolfgang Reichert explained the special cycles for 5-axis programming on the Siemens 840 D control used. Various adjustments to machine data and control parameters were then tested directly on the machine and optimized with regard to the test piece. With these adjusted parameters, the team around Hans Vogler produced several test pieces on the milling machine in the second step, which were then examined with regard to running time and geometrical deviations that occurred.

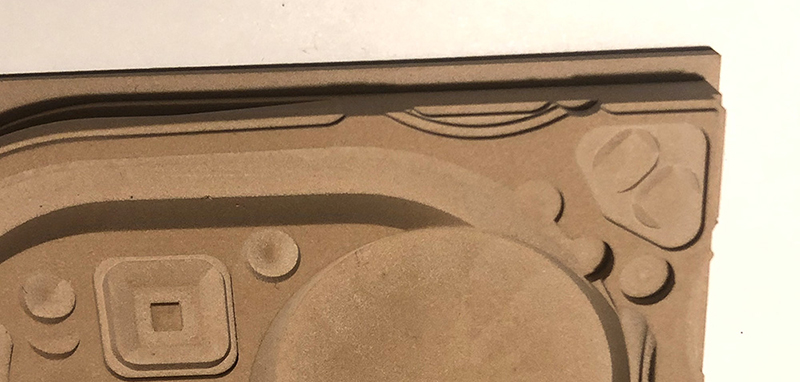

The test pieces produced by the OPTImill FU5 showed hardly any detectable defects even under the camera microscope. In order to underline the precise operation of the OPTIMUM CNC machine, archive photos with negative examples were finally used, which once again illustrated the outstanding result of the 5-axis machining center from OPTIMUM.

Conclusion:

With this perfectly crafted test piece, the OPTImill FU5 stands any comparison with competitors in terms of quality, precision and price-performance ratio.

Das Video zum Test finden Sie hier