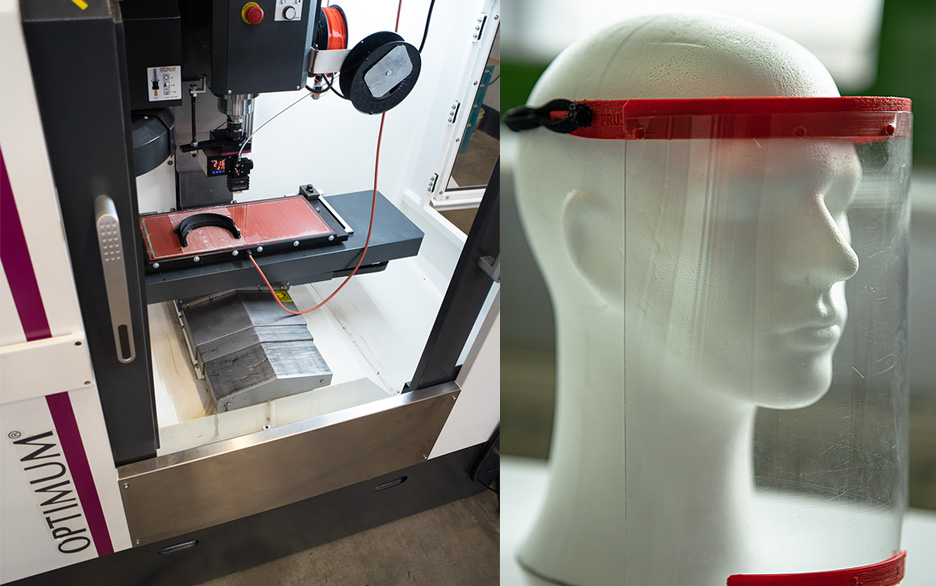

Hallstadt-based company starts manufacturing face shields for hospitals using innovative 3D printing technology

Stürmer, a machine manufacturer and machinery wholesaler based in Hallstadt near Bamberg in Upper Franconia, Germany, has set up a 3D print head, recently brought to production readiness for industrial use in conjunction with the University of Trier, to manufacture urgently needed face shields. Since the end of last week, the required face shields for doctors, hospital and nursing staff can be produced using the CNC milling machines of its OPTIMUM brand in a 3D printing process. As a first step, starting next week, these are to be made available to hospitals in the Bamberg area and northern Bavaria free of charge.

The great advantage of the technology used is that such plastic parts can be additionally produced with the OPTIMUM 3D printhead OPTImill 3X in unmanned secondary shifts on commercially available CNC milling machines that are otherwise used in production plants during the main shifts. With the start of the day shifts, these parts produced "on the side" can then be finished with little manual effort and immediately distributed to the hospitals.

Of course, the quantities cannot be compared with those achieved with conventional industrial plastics processing machines, such as those used for injection molding. However, there are no expensive acquisition costs for tools and the additional costs for setup and machine operation are also extremely low. In addition, many different variants can easily be produced according to individual requirements, even in the smallest batch sizes. This only requires changes in the machine control programs, but does not require expensive plastic molds, which would have to be manufactured a long time in advance.

For the production of the plastic components, Stürmer uses PLA filament, which is particularly suitable for manufacturing the required components due to its low weight and flexibility. In addition, this material is obtained from renewable and natural raw materials and is therefore biodegradable without any further treatment.

Stürmer has printed the first prototypes of the protective shields on its OPTImill F 80 3-axis milling center in its logistics center in Pettstadt near Bamberg. The first products are to be delivered to hospitals starting next week. The design file required was provided by Prusa Research a.s. in the Czech Republic, a company specializing in 3D printing processes, that made the file available specifically for combating the Corona pandemic. Kilian Stürmer, owner of the group, did not hesitate for a moment and was immediately enthusiastic about the idea of joining forces across national borders to fight the pandemic and provide several milling machines for the production of the face shields: "We are very pleased to combine this great concept of our Czech neighbors with our know-how and decades of experience in the field of CNC milling and thus support those people who are currently working unconditionally for the health of us all".