| Cooling | |

|---|---|

| Cooling type | AF |

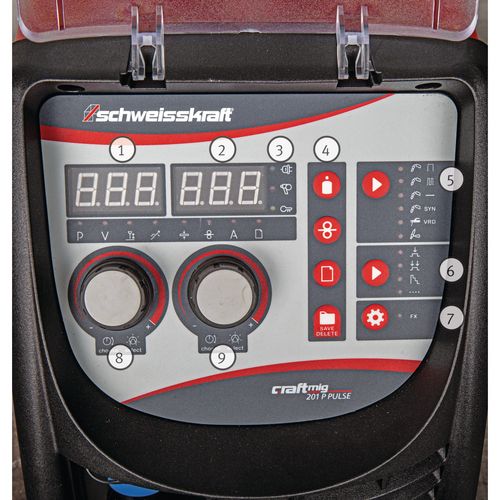

Pulse inert gas welder

CRAFT-MIG 253 Pulse Special offer set

modern MIG welder for professional use

2.026,99

EUR excl. Tax / pc(s).

2.412,12

EUR incl. 19% Tax / pc(s).

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 1072253SET

Productdetails

Basic Features

Method

- MIG/MAG

- TIG (DC)

- Electrodes

Sheet thicknesses

- from 0.8 mm steel and stainless steel (MAG)

- from 1.0 mm for aluminum (MIG)

Base materials

- Unalloyed and low-alloy materials (S235JR)

- High-alloy materials (stainless steel)

- Aluminum alloy

- Filler wire

Typical applications

- Locksmith, mechanical engineering, assembly

- Car workshop, plumber

- Maintenance, repair

Description

- Pulse function: Significantly less rework due to low-spatter welding

- Best welding results due to safe ignition and stable arc

- Synergy function: By preselecting wire Ø, material and gas, automatic calculation of voltage and wire feed

- Accurate setting of welding parameters via digital display with job memory

- Fewer faults therefore higher quality

- The quiet running fans dissipate heat well from the units and result in a high duty cycle

- Arc-Force control: Due to the internal monitoring of welding current and voltage, short circuits are resolved quickly and safely. This stabilises the arc and the electrode can be processed without any problems

- Less welding dust

- Filler wires can be easily welded by simply reversing the polarity

- Suitable for operation on a power generator

- Large range of functions: MIG/MAG (Pulse, Dual Pulse, Synergic, Manual), TIG Lift Arc, E-Hand

| Dimensions and weights | |

|---|---|

| Length approx. | 750 mm |

| Width/depth approx. | 240 mm |

| Height approx. | 450 mm |

| Weight approx. | 28,5 kg |

| Duty cycle | |

|---|---|

| Duty cycle at Imax. 40°C | 60 % |

| Current at 60% DC 40°C | 250 A |

| Current at 100% DC 40°C | 195 A |

| Electrical connections | |

|---|---|

| Power consumption in idle mode | 24 W |

| Electrical Data | |

|---|---|

| Supply voltage | 400 V |

| Mains frequency | 50/60 Hz |

| Input | |

|---|---|

| Explanation power factor | MMA: 0.68 | TIG: 0.66 | MIG: 0.67 cos phi |

| Efficiency | 88 % |

| Product information EU 2023/2854 | |

|---|---|

| Type of the generated data | Usage data |

| Format of the generated data | Common, machine-readable formats such as JSON |

| Amount of data | Up to 5 MB |

| Continuous data generation in real time | Yes |

| Setting range | |

|---|---|

| MIG/MAG | 20 – 250 A |

| TIG DC | 10 – 250 A |

| Electrode | 10 – 250 A |

| Standards and certifications | |

|---|---|

| Standard | EN 60 974-1; -10 |

| EMC class | A |

| Explanation EMC class | This Class A welding equipment is not intended for use in residential areas where power is supplied by a public low-voltage power supply system. |

| Marking | CE |

| Wire feed | |

|---|---|

| Wire feet unit | 4 Rollers |

| Speed from to | 1,5 – 24 m/min |

| VPE | 1 |

Packaging unit: 1

- Welding torch MB 25, 4 m

- Earth cable with earth clamp 300A, 35 mm², 4 m

- Gas hose 12x6 mm, 4 m

- Pressure reducer Argon/CO2, large

- Feed rollers Ø 0.8 – 1.0 steel

- Welding helmet VarioProtect XXL-W

- Welding glove Basic size L / size 9

Dr.-Robert-Pfleger-Str. 26

96103 Hallstadt

Deutschland / Germany

info@stuermer-maschinen.de

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.