| Cross table | |

|---|---|

| Clearance vertical spindle - cross table | 255 mm |

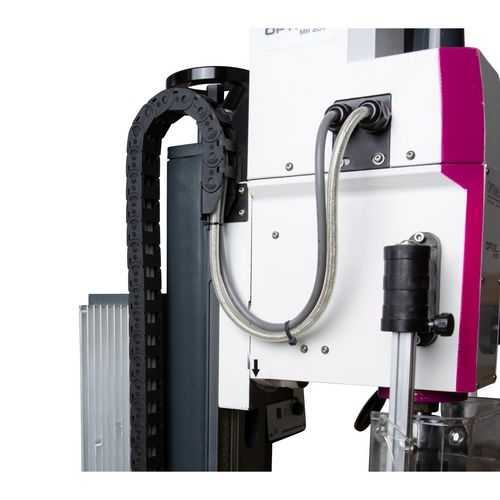

Drilling-milling machine

OPTImill MH 20VLD

Stable drilling/milling machines with electronically infinitely variable drive and with greater travel in the X-axis and digital readout DRO 5

3.069,01 EUR incl. 19% Tax / pc(s).

Promotional price *

2.469,00 EUR excl. Tax / pc(s).2.938,11 EUR incl. 19% Tax / pc(s).

Prices are recommended retail prices. Retailer prices may vary.

* Promotional price valid until 28.02.2026 in Germany.

Art.-No. 3338133

Productdetails

- Precisely built

- High concentricity due to tapered roller bearings ≤ 0.015 mm measured in the quill

- Motor with two-stage gear ratio for powerful transmission of motor power

- Manual quill feed with fine feed

- Powerful DC motor with permanent current monitoring

- Safety electronics in 24 Volt version

- Control electronics with integrated relay control

- Clear control panel with user-friendly membrane keyboard

- Easy-to-read digital display for speed and drilling depth

- Solid and large dimensioned cross table, precisely finished with T-slots and adjustable wedge strips

- Adjustable end stops

- Stable dovetail guide with adjustable wedge strips

- Emergency stop impact switch

- Drilling and milling head can be tilted by ± 60°

- Fine milling feed

- Forward/reverse rotation

- Machine lamp

- Double-row angular contact ball bearings in the axes, adjustable without play

- Height-adjustable protective screen with microswitch, against flying chips and parts, for the greatest possible protection of the user

- X, Y and Z axes with prepared groove for the subsequent assembly of magnetic tapes

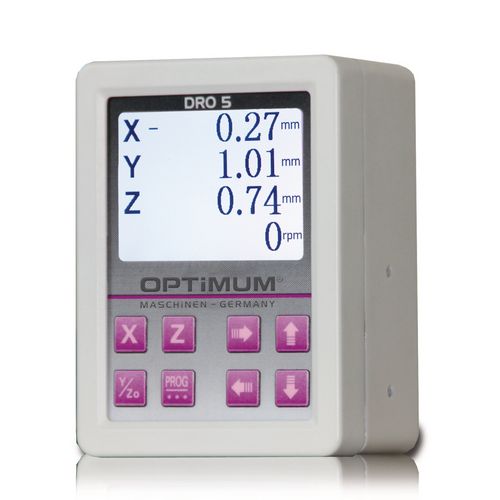

- With digital position indicator DRO 5

You will receive the 3-year Stürmer warranty for this item when you register online.

| Dimensions and weights | |

|---|---|

| Length approx. | 770 mm |

| Width/depth approx. | 714 mm |

| Height approx. | 917 mm |

| Weight approx. | 99 kg |

| Drilling/milling head | |

|---|---|

| Mill head swivel range | ± 60 ° |

| Drilling/milling output | |

|---|---|

| Max. size milling head | 52 mm |

| Max. size shaft milling cutter | 20 mm |

| Drilling performance steel (S235JR) | 16 mm |

| Continuous drilling performance steel (S235JR) | 12 mm |

| Electrical Data | |

|---|---|

| Supply voltage | 230 V |

| Mains frequency | 50 Hz |

| Milling table horizontal | |

|---|---|

| Table length | 700 mm |

| Table width | 180 mm |

| T-groove size | 12 mm |

| T-groove number | 3 |

| T-groove spacing | 63 mm |

| Max. load bearing capacity | 50 kg |

| Standards and certifications | |

|---|---|

| Standard | DIN EN 55011 |

| EMC level | C1 |

| Travel | |

|---|---|

| X axis manual | 480 mm |

| Y axis manual | 175 mm |

| Z axis manual | 210 mm |

| Vertical spindle | |

|---|---|

| Reach | 170 mm |

| Spindle chuck | MK 2 |

| Speed range | 100 – 3000 min¯¹ |

| Number of gears | 2 |

| Speed control | electronically adjustable |

| Drive motor output S6-30 % operation | 0,75 kW |

| VPE | 1 |

| Sicherheits- und Warnhinweise | |

| Safety and warning notices |

Packaging unit: 1

- Tapered mandrel MK2/B16

- Tightening rod M 10

- Operating tool

| Digital position indicator | DRO 5 |

Dr.-Robert-Pfleger-Str. 26

Deutschland / Germany

96103 Hallstadt

info@optimum-maschinen.de

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.