| Pressing force | 100 t |

| Bending length | 3150 mm |

| Distance between columns | 2600 mm |

| Stroke | 250 mm |

| Rapid mode | 160 mm/s |

| Bending speed from to | 1 10 mm/s |

| Retraction | 100 mm/s |

| Table height | 930 mm |

| Table width | 60 mm |

| X axis stroke from to | 5 - 750 mm |

| X axis speed | 500 mm/s |

| Oil tank capacity | 232 l |

| VPE | 1 |

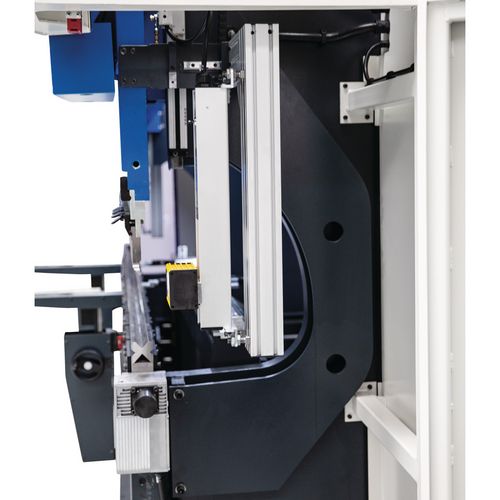

CNC-controlled, hydraulic press brake

GBP PLUS 30100

With 4 driven axes, motorized crowning and manual upper tool quick clamping

Price upon request

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 4273010

Productdetails

Standard version:

- Graphical 2D CNC control DELEM DA-58T with offline software TL

- Two linear encoders (GIVI) on Press bar for checking the desired position

- High-quality linear encoders with an accuracy of 0.01 mm

- CNC-controlled backgauge with two backgauge fingers

- X-axis linearly guided and driven by ball screws via servomotor

- R-axis guided linearly and driven by ball screws via servomotor

- Backgauge fingers on linear guides manually adjustable laterally

- Safety laser Fiessler AKAS LC -II M with press safety control FMSC

- CNC-controlled, motorized crowning device WILA to compensate for the spring deflection

- Control panel on the right side of the machine on a swiveling arm

- Solid and low-maintenance flat guide of the press beam

- Manual top tool clamping (lateral removal), Promecam system / Amada

- Top tool (Promecam/Amada), height 105 mm (3 x 835 mm / 1 x 805 mm sectioned)

- Multi-V die, height 60 mm, V-openings 16/22/35/50 mm (3 x 835 mm / 1 x 805 mm sectioned)

- Mobile foot control unit (BERNSTEIN) with emergency stop function and safety cable

- Foot pedal with two switches (press bar up/down) and safety step in the down switch

- Two front support arms that can be quickly adjusted on the side on the linear guide

- All linear guides and carriages from HIWIN motion control

- Control-controlled oil quantity distribution between the cylinders

- Monitoring of the relative cylinder position during bending process

- Direct programming of the bending angle via control

- Programmable bending and retraction speed and pressing time

- Manual, semi-automatic or automatic working mode selectable

- Honed cylinders, made from one block for highest accuracy and durability

- Hydraulic components from HAWE (valves) and KCL Hydraulic (pump)

- Electrical components from Schneider and Mitsubishi Electric

- Large hydraulic tank to maintain the correct oil temperature

- Hydraulic system protected by pressure relief valve

- Drive motors protected by appropriate circuit breakers

- Machine body in a particularly heavy and tension-free welded construction

- Side doors easy to open and monitored by safety switches

- Rear area protection using a light barrier system from REER Italy

- Illumination of the work area by means of an LED bar in the press beam cover

Special accessories:

- Controls (DELEM DA-66T-2D, DELEM DA-69T-3D, Cybelec CybTouch 15, Cybelec CybTouch 19-2D, Cybelec CybTouch 19 MX-3D)

- Back gauge X/R/Z1/Z2 with X travel = 750 mm

- Back gauge X/R/Z1/Z2 + Delta X (200 mm) with X travel = 750 mm

- Backgauge X/X2/R1/R2/Z1/Z2 (tower version)

- Hydraulic upper tool clamp WILA Pro

- Hydraulic die clamp WILA Pro

- Manual central lubrication

- Automatic central lubrication

- Bending aids with motorized height adjustment - can be moved laterally

- Additional front support arm (without handwheel height adjustment)

- Additional rear stop finger (manually movable)

- Parking area 1,000 mm for front support arms or bending aids

- Oil cooler

- Oil warmer

- Special sizes on request

- Graphical 2D CNC control DELEM DA-58T with offline software TL

- Two linear encoders (GIVI) on Press bar for checking the desired position

- High-quality linear encoders with an accuracy of 0.01 mm

- CNC-controlled backgauge with two backgauge fingers

- X-axis linearly guided and driven by ball screws via servomotor

- R-axis guided linearly and driven by ball screws via servomotor

| Dimensions and weights | |

|---|---|

| Length approx. | 4200 mm |

| Width/depth approx. | 1800 mm |

| Height approx. | 2900 mm |

| Weight approx. | 9000 kg |

| Electrical Data | |

|---|---|

| Drive motor output | 11 kW |

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Sicherheits- und Warnhinweise | |

| Safety and warning notices |

Packaging unit: 1

| Crowning | motor |

| Control system | Graphic 2D CNC touchscreen control Delem DA-58T |

| Drive | hydraulic |

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.

Accessories

Optional parts

Optional parts can not be retrofitted and are available only when ordering new machines.