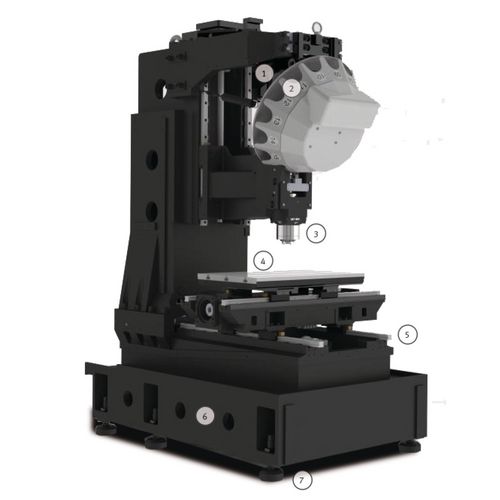

- Robust design

- Servo tool changer with 21 tool slots

- All linear guides with stainless steel covers

- Automatic central lubrication

- Machine lamp in workspace

- Portable, electronic handwheel with confirm button and emergency stop mushroom button. Greatly facilitates running in of programs

- Coolant system

- Tool change automatic

- Solid, precise milling table, precise surface machining

- Generously designed access doors to reduce cleaning and maintenance time to a minimum

- SIEMENS servodrive on all axes

- Chip conveyor, belt type

- Chip cart

- Inline spindle 16000 rpm

- Ball screws on all axes

- Oil cooler compensates for temperature fluctuations at the main spindle

| Control |

|---|

| Type | Sinumerik 828D |

| System software | SW 28x |

| CNC memory | 8 MB |

| Set change time | 1 ms |

| Look Ahead | 150 |

| Number of tools | 512 |

| Cooling lubricant system |

|---|

| Coolant pump(s) drive power | 370 W |

| Tank capacity | 120 l |

| Dimensions and weights |

|---|

| Length approx. | 2315 mm |

| Width/depth approx. | 2194 mm |

| Height approx. | 2325 mm |

| Weight approx. | 3800 kg |

| Drilling/milling output |

|---|

| Max. size milling head | 63 mm |

| Max. size shaft milling cutter | 25 mm |

| Electrical connections |

|---|

| Total rated value | 45 kVA |

| Electrical Data |

|---|

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Fast motion speed |

|---|

| X axis | 40000 mm/min |

| Y axis | 40000 mm/min |

| Z axis | 40000 mm/min |

| Feed motor drive power |

|---|

| X axis feed continuous operation S1 | 2,32 kW |

| Y axis feed continuous operation S1 | 2,32 kW |

| Z axis feed continuous operation S1 | 3,3 kW |

| X axis 30% operation S6 | 4,1 kW |

| Y axis 30% operation S6 | 4,1 kW |

| Z axis 30% operation S6 | 6,5 kW |

| Feed motor torque |

|---|

| X axis continuous operation S1 | 7,4 Nm |

| Y axis continuous operation S1 | 7,4 Nm |

| Z axis continuous operation S1 | 10,5 Nm |

| X axis 30% operation S6 | 14 Nm |

| Y axis 30% operation S6 | 14 Nm |

| Z axis 30% operation S6 | 21 Nm |

| Feed speed |

|---|

| Acceleration X, Y, Z axis | 2 m/s² |

| Milling table horizontal |

|---|

| Table length | 650 mm |

| Table width | 400 mm |

| Min. clearance vertical spindle - milling table | 150 mm |

| Max. clearance vertical spindle - milling table | 450 mm |

| T-groove size | 14 mm |

| T-groove number | 3 |

| T-groove spacing | 125 mm |

| Max. load bearing capacity | 250 kg |

| Pneumatic connection |

|---|

| Operating pressure | 6 bar |

| Precision |

|---|

| Repetition accuracy | ± 0.006 mm |

| Positioning accuracy | ± 0.005 mm |

| Product information EU 2023/2854 |

|---|

| Type of the generated data | Usage data |

| Format of the generated data | Common, machine-readable formats such as JSON |

| Amount of data | Up to 5 MB |

| Continuous data generation in real time | Yes |

| Data storage location | On the device |

| Data access | Via physical interfaces |

| Further information | In the operating instructions or at info@stuermer-maschinen.de |

| Travel |

|---|

| X axis automatic | 500 mm |

| Y axis automatic | 400 mm |

| Z axis automatic | 300 mm |

| Turret |

|---|

| Design | Servo |

| Number of tool slots | 21 Tools |

| Max. tool diameter | 80 mm |

| Max. tool length | 80 mm |

| Max. tool weight | 3 kg |

| Tool change time chip to chip (C to C) | 7.33 s |

| Vertical spindle |

|---|

| Spindle chuck | BT 30 |

| Speed | 16000 min¯¹ |

| Explanation speed range | Please note that the maximum spindle speed must be reduced by approx. 20 % in continuous operation. |

| Spindle centre to Z axis cover | 400 mm |

| Drive motor output continuous operation S1 | 12 kW |

| Drive motor output S6-30 % operation | 22,8 kW |

| Torque drive motor continuous operation S1 | 38 Nm |

| Torque drive motor S6-30 % operation | 116 Nm |

Unit: pc(s).

Packaging unit: 1

Optimum Maschinen Germany GmbH

Dr.-Robert-Pfleger-Str. 26

Deutschland / Germany

96103 Hallstadt

info@optimum-maschinen.de