- Braced machine bed made of gray cast iron

- Elaborate spindle bearing

- Emergency stop impact switch

- Central lubrication

- Reference switch

- Maintenance-friendly protective housing

- Rear access door for maintenance

- Safety switch on the front sliding door

- Revolving revolver is behind the center of rotation (left-hand turning tool)

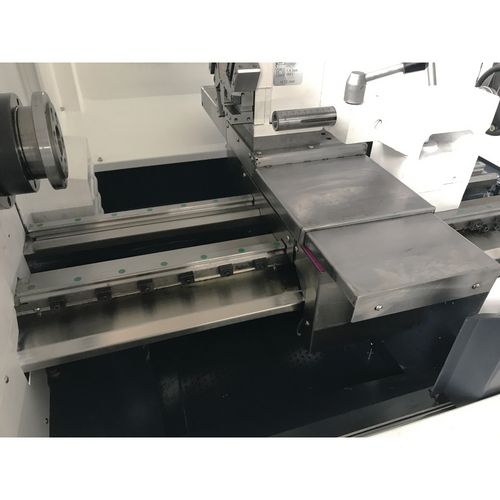

- Linear guide

- Software package "SINUMERIK 808D on PC" included. (Practical training software, with it Workpieces can be programmed and simulated offline on the PC. Download for free at www.cnc4you.com)

| Cooling lubricant system |

|---|

| Coolant pump output | 95 W |

| Tank capacity | 25 l |

| Dimensions and weights |

|---|

| Length approx. | 1655 mm |

| Width/depth approx. | 1590 mm |

| Height approx. | 1955 mm |

| Weight approx. | 832 kg |

| Electrical connections |

|---|

| Total rated value | 3.75 kVA |

| Electrical Data |

|---|

| Drive motor output | 2,2 kW |

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Feed speed |

|---|

| X axis | 10000 mm/min |

| Z axis | 12000 mm/min |

| Hydraulic system |

|---|

| Tank capacity | 25 l |

| Motor torque |

|---|

| X axis | 1.3 nm |

| Z axis | 2,4 Nm |

| Motor(s) |

|---|

| Drive motor torque | 14 nm |

| Torque at the spindle | 28 nm |

| Precision |

|---|

| Repetition accuracy | ± 0.01 mm |

| Positioning accuracy | ± 0.01 mm |

| Product information EU 2023/2854 |

|---|

| Type of the generated data | Usage data |

| Format of the generated data | Common, machine-readable formats such as JSON |

| Amount of data | Up to 5 MB |

| Continuous data generation in real time | Yes |

| Data storage location | On the device |

| Data access | Via physical interfaces |

| Further information | In the operating instructions or at info@stuermer-maschinen.de |

| Speed range |

|---|

| Speed range | 40 – 4000 min¯¹ |

| Spindle |

|---|

| Spindle chuck | (DIN 6350) A2-3 |

| Spindle bore/rod passage diameter | 30 mm |

| Spindle taper | 5C |

| Tailstock |

|---|

| Chuck | MK2 |

| Quill stroke | 120 mm |

| Quill diameter | 30 mm |

| Travel |

|---|

| Travel X axis | 145 mm |

| Travel Z axis | 465 mm |

| Turret |

|---|

| Type | electrical |

| Number of tool slots | 6 St |

| Max. chuck height, width square | 16 mm |

| Max. chuck diameter drilling rod | 16 mm |

| Work areas |

|---|

| Center height | 169 mm |

| Distance between center | 430 mm |

| Swing diameter above machine bed | 300 mm |

| Swing diameter above planing slide | 200 mm |

| Bed width | 180 mm |

Unit: pc(s).

Packaging unit: 1

- Coolant system

- machine lamp

- operating tool

Optimum Maschinen Germany GmbH

Dr.-Robert-Pfleger-Str. 26

Deutschland / Germany

96103 Hallstadt

info@optimum-maschinen.de