| Drive output | |

|---|---|

| Lower motor drive power (joints) | 4 kW |

| Upper horizontal spindle motor (thickness) | 4 kW |

| Vertical spindles motor | 5.5 kW |

| Feed motor(s) | 2,2 kW |

Profiling machine

CASADEI MATRIX 230/4

With 4 spindles A-type with program control and motorized height adjustment

32.850,00

EUR excl. Tax / pc(s).

39.091,50

EUR incl. 19% Tax / pc(s).

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 5224010

Productdetails

- For workpieces up to max. 230 x 120 mm

- Chip removal adjustable up to 6 mm

- With direct startup

- Pipe-braced monoblock machine stand ensures low-vibration operation

- Inlet guide via precise parallelogram system comfortably manually adjustable

- Pre-adjustment of the workpiece on the right side by means of a jointing cutter on the dressing spindle for precise planing

- Extra long infeed table with ground cast surface for precise guidance of long and twisted workpieces

- Replaceable hard chrome insert with table lips in front of the vertical spindles

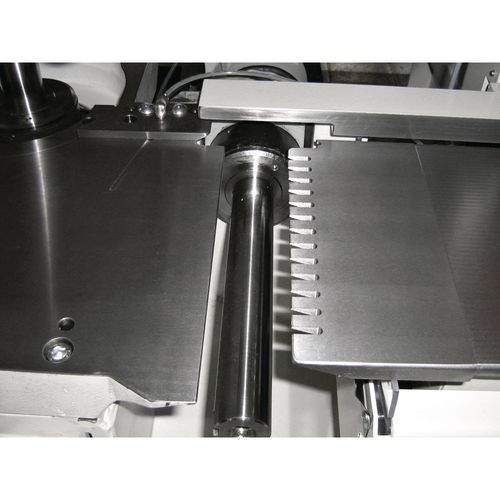

- Torsion-resistant ribbed steel feed beam for precise work

- Simultaneous adjustment of the feed carrier and the upper horizontal spindle (motorized adjustment on request)

- Steel feed rollers, hardened and toothed, with mechanical pressure

- Precise and smooth insertion of the workpiece through the feed roller in front of the dressing spindle (infinitely variable from 4 to 20 m / min.)

- Spindle sleeve (100 mm) made of cast iron

- The adjustment of the working aggregates takes place at the front of the machine when the full protection cabin is closed

- Mechanical decimal displays for displaying the working width and height

- Full protection cabin with noise-reducing fairing, control window and safety microswitch

O execution

- With electronic programming unit with microprocessor for positioning the left vertical and the upper horizontal spindle

- Storage capacity 99 programs

- Motorized height adjustment of the feed unit and the upper horizontal spindle

| Extraction port | |

|---|---|

| Extraction port diameter | 1 x 150/3 x 120 mm |

| Feed | |

|---|---|

| Speed | 4 – 20 m/min |

| Roller diameter | 140 mm |

| Infeed table | |

|---|---|

| Infeed table length | 2000 mm |

| Infeed guide adjustment range at the infeed table | 10 mm |

| Noise emission | |

|---|---|

| Emissions sound pressure level at the inlet section for idling EN ISO 11202:1995 | 79.0 dB(A) |

| Emissions sound pressure level at the inlet section for processing EN ISO 11202:1995 | 88.2 dB(A) |

| Emissions sound pressure level at the outlet section for idling EN ISO 11202:1995 | 72.5 dB(A) |

| Emissions sound pressure level at the outlet section for processing EN ISO 11202:1995 | 84.9 dB(A) |

| Sound power level Lw in idling EN ISO 3746:1995 | 91.0 dB(A) |

| Sound power level Lw for processing EN ISO 3746:1995 | 102.9 dB(A) |

| Explanation about noise emission | 2009 standards |

| Spindles | |

|---|---|

| Cutting depth | 6 mm |

| Speed | 6000 min¯¹ |

| Diameter | 40 mm |

| Horizontal spindle usable length | 250 mm |

| Vertical spindle usable length | 140 mm |

| Horizontal spindles axial adjustment | 40 mm |

| Vertical spindles axial adjustment | 40 mm |

| Min. tool diameter, initial lower horizontal spindle | 120 mm |

| Max. tool diameter, initial lower horizontal spindle | 140 mm |

| Min. tool diameter, vertical spindles | 100 mm |

| Max. tool diameter, vertical spindles | 180 mm |

| Min. tool diameter, second lower horizontal spindle | 100 mm |

| Max. tool diameter, second lower horizontal spindle | 180 mm |

| Workpiece/finished part dimensions | |

|---|---|

| Max. finished part width/depth | 230 mm |

| Max. finished part height | 120 mm |

| Min. workpiece width | 25 mm |

| Min. workpiece height | 6 mm |

| VPE | 1 |

Packaging unit: 1

- Infeed table made of tubular steel construction with hardened insert in front of the dressing spindle

- Simultaneous manual adjustment of the hollow beam and the upper horizontal spindle

- Controls on the front of the machine with mechanical decimal displays

- Adjustment system QUICK SET

- Protective cabin with noise-reducing fairing, control window, safety micro and interior lighting

- Add. Feed device (pre-dressing) with quick-lock

- Mauelle pump for lubrication of worktable and steel guides

- Selector switch for feed with switching pulses feed

- lower horizontal spindle (dressing spindle)

- right vertical spindle

- left vertical spindle

- upper horizontal spindle

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.

Optional parts

Optional parts can not be retrofitted and are available only when ordering new machines.