| Cooling lubricant system | |

|---|---|

| Coolant pump(s) drive power | 0.37 kW |

| Tank capacity | 190 l |

CNC milling machine

OPTImill F 150E

The compact solution for small batch production in medium-sized companies

Price upon request

Prices are recommended retail prices. Retailer prices may vary.

Art.-No. 3501150

Productdetails

- Carousel tool changer with 16 tool places

- All linear guides with stainless steel covers

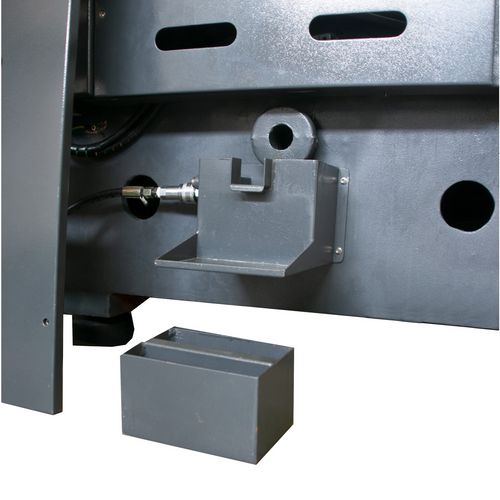

- Automatic central lubrication system

- Siemens main spindle motor

- Servo drive from SIEMENS in all axes (closed control loop)

- Span conveyor in belt design ensures efficient chip removal

- Span carriage

- Max. Spindle speed 10,000 min-1

- Machine light in the working area

- Portable, electronic handwheel with enabling switch and emergency stop pushbutton. Simplifies the running-in of programs considerably

- Coolant device with 190-litre coolant tank

- Tool change takes place automatically or at the push of a button (electro-pneumatic tool clamping device)

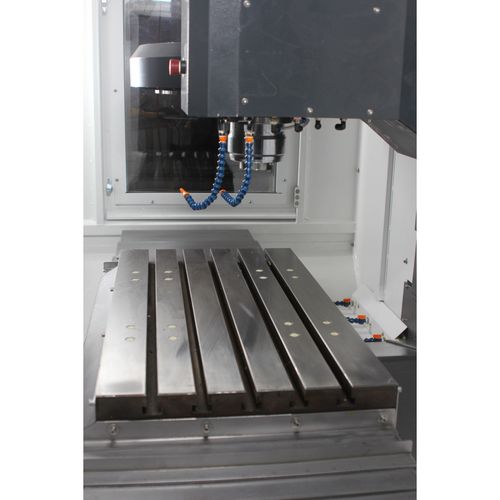

- Massive, precise millingtable, largely dimensioned and precisely surface machined

- Access doors very generously designed to reduce cleaning and maintenance time to a minimum

- Software package "SINUMERIK 808D on PC" included (Practical training software so that workpieces can be programmed and simulated offline on the PC. Software can be downloaded free of charge from www.cnc4you.com.)

SINUMERIK 808 ADVANCED - CNC technology from the technology leader, coupled with a revolutionary operating concept

Increase in productivity in production

- The SINUMERIK 808D ADVANCED control is a panel-based CNC control. This compact and user-friendly entry-level solution is used for simple milling applications. Features such as easy operation, commissioning and maintenance are the perfect basis for equipping CNC machines.

- Thanks to its technology-specific features, the SINUMERIK 808D ADVANCED control is perfectly preconfigured for milling. Due to the hardware and software extensions, the SINUMERIK 808D ADVANCED also offers sufficient performance for simple milling functionalities for mold and tool making.

Compact and robust

- Thanks to a panel-based CNC design with few interfaces and an IP65-rated control panel, the SINUMERIK 808D ADVANCED is perfectly prepared for use in harsh environments. The small dimensions allow the use in compact machines

INCLUDES

- RJ45 Ethernet port

- 8.4" color LCD display with 800 x 600 resolution

- Prepared forr Remote maintenance

- AST function; allows easy optimization for higher requirements on dynamics and accuracy

- absolute encoder / no homing necessary

- Higher accuracy

| Dimensions and weights | |

|---|---|

| Length approx. | 3420 mm |

| Width/depth approx. | 2050 mm |

| Height approx. | 2400 mm |

| Weight approx. | 4500 kg |

| Drilling/milling output | |

|---|---|

| Max. size milling head | 80 mm |

| Max. size shaft milling cutter | 38 mm |

| Electrical connections | |

|---|---|

| Total rated value | 15 kW |

| Electrical Data | |

|---|---|

| Supply voltage | 400 V |

| Mains frequency | 50 Hz |

| Fast motion speed | |

|---|---|

| X axis | 20000 mm/min |

| Y axis | 20000 mm/min |

| Z axis | 20000 mm/min |

| Feed motor torque | |

|---|---|

| X axis continuous operation S1 | 9.55 Nm |

| Y axis continuous operation S1 | 9.55 Nm |

| Z axis continuous operation S1 | 16.7 Nm |

| Milling table horizontal | |

|---|---|

| Table length | 900 mm |

| Table width | 500 mm |

| Min. clearance vertical spindle - milling table | 100 mm |

| Max. clearance vertical spindle - milling table | 600 mm |

| T-groove size | 18 mm |

| T-groove number | 5 |

| T-groove spacing | 80 mm |

| Max. load bearing capacity | 350 kg |

| Pneumatic connection | |

|---|---|

| Operating pressure | 6,0 bar |

| Precision | |

|---|---|

| Repetition accuracy | ± 0,008 mm |

| Positioning accuracy | ± 0,008 mm |

| Travel | |

|---|---|

| X axis automatic | 750 mm |

| Y axis automatic | 500 mm |

| Z axis automatic | 500 mm |

| Turret | |

|---|---|

| Number of tool slots | 16 Tools |

| Max. tool diameter adjacent slots free | 180 mm |

| Max. tool diameter | 90 mm |

| Max. tool length | 250 mm |

| Max. tool weight | 8 kg |

| Tool change time chip to chip (C to C) | 20 s |

| Vertical spindle | |

|---|---|

| Spindle chuck | BT 40 |

| Speed range | 10 – 10000 min¯¹ |

| Drive motor output continuous operation S1 | 7,5 kW |

| Drive motor output S6-30 % operation | 11.25 kW |

| Torque drive motor continuous operation S1 | 48 Nm |

| Torque drive motor S6-30 % operation | 72 Nm |

| VPE | 1 |

Packaging unit: 1

If a guarantee is shown in the article description and/or in the description of the scope of delivery, your legal rights of liability for defects towards your seller remain unaffected. For the scope, duration, content and the guarantor, please refer to the guarantee conditions. We are not liable for printing errors, mistakes or incorrect presentation. Technical and optical changes are reserved. Fig. partly with optional accessories. Delivery is made exclusively according to our terms of delivery and payment. The sale is carried out via the specialized trade.

Accessories

Optional parts

Optional parts can not be retrofitted and are available only when ordering new machines.